Telemicroscopia per la Caratterizzazione di Motori a effetto Hall

Stato: completed

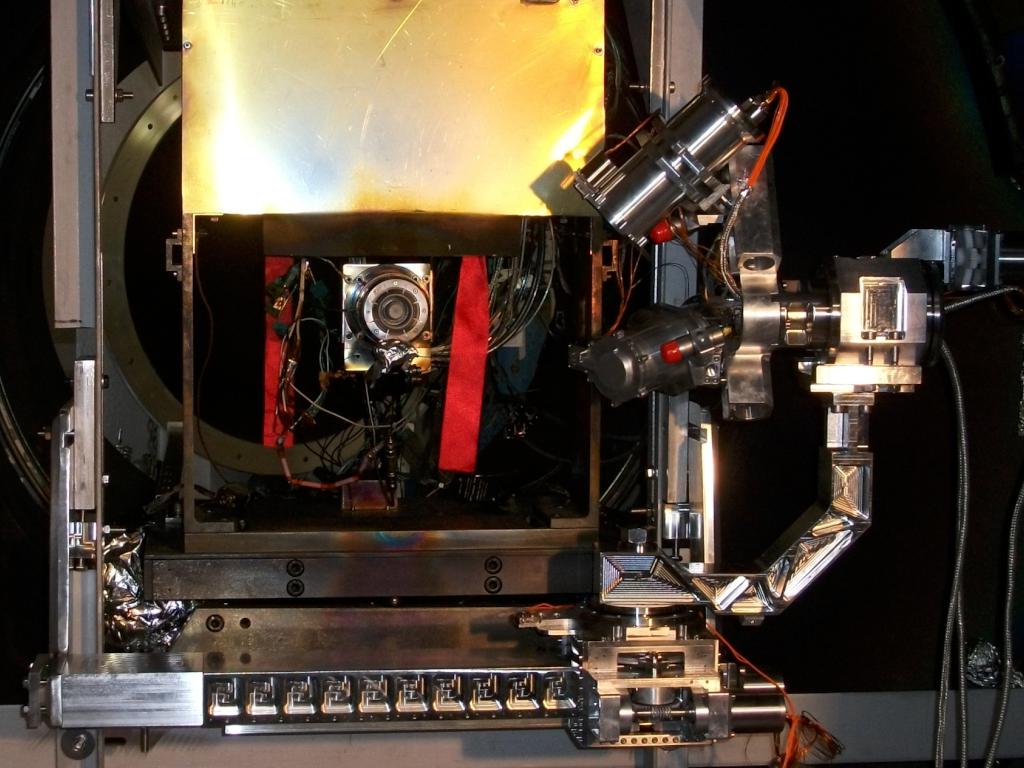

Attività: Detailed design, procurement, transport at customer premises, alignment

Date: 2010

Client: Sitael SpA

Category: space

Credits: EIE Space Technologies Srl, Sitael SpA

Overview

Hall-effect thrusters (HET) represent a fundamental technology for the realization of satellite platforms. These thrusters are used for different aspects, as controlling the framework on board the commercial satellite located in the geocentric orbit as well as the main propulsion on board of small-scale robotic space probes and for the inclusion from a parking orbit to the geostationary one.

These motors are characterized by a modest boost – this is the technical word to define the force given by the engine – which has a high level of specific impulse, which shows the ratio between the impulse given by the motor - that stands for the variation of the momentum of the probe due to the action of the motor – for unit of used propellant.

These features cannot be used during launch phases – this is because the maximum thrust created by Hall-effect thrusters is not enough to raise the motors – but they are fundamental for into-orbit maneuvers, where it is necessary to efficiently use resources and to not combat air resistance and gravity.

These motors’ technology is based on the acceleration given by potential difference of propellant ion. The propellant is made of Xenon gas, even if using other gases such as Krypton, Argon and Bismuto is possible too. Gas is originally neutral; it goes through an ionization process, which is caused by free electrons inside a magnetic field generated in the motor. The potential applied between the anode and the cathode speeds up heavy ion. The different Larmor radius between ion and electrons – a measure proportionated to their mass classifies the deflection of an ion that moves within an electromagnetic field – makes the haze of electrons be confined , while the heavy ones are expelled.

In fact, some electrons manage to escape the containment, colliding with the walls of the motor and spreading to the anode.

These exhaust streams limit the efficiency and emerge in a macroscopic way as an erosion of some of the ceramic parts that constitute the motor’s structure.

Technical Specifications

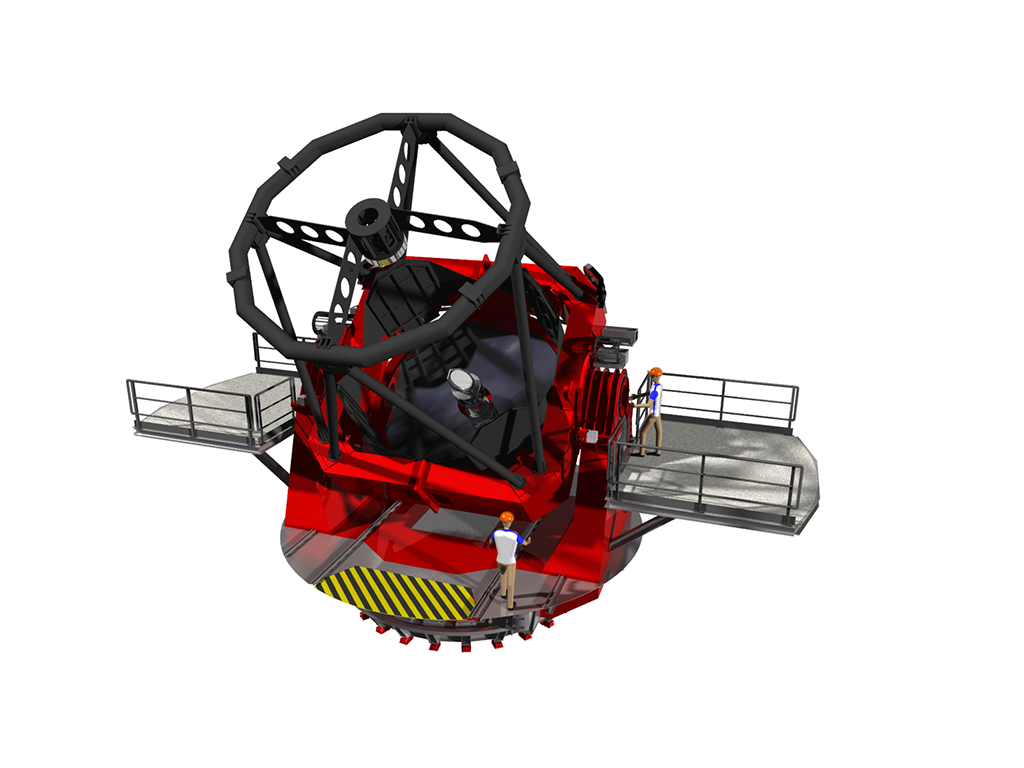

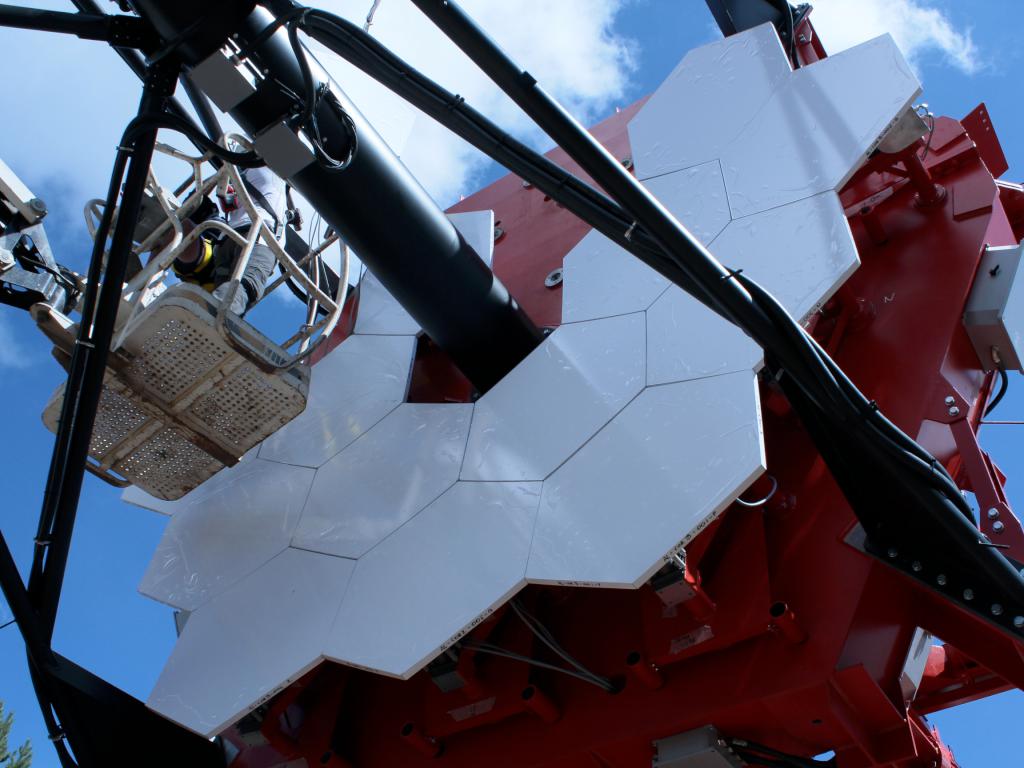

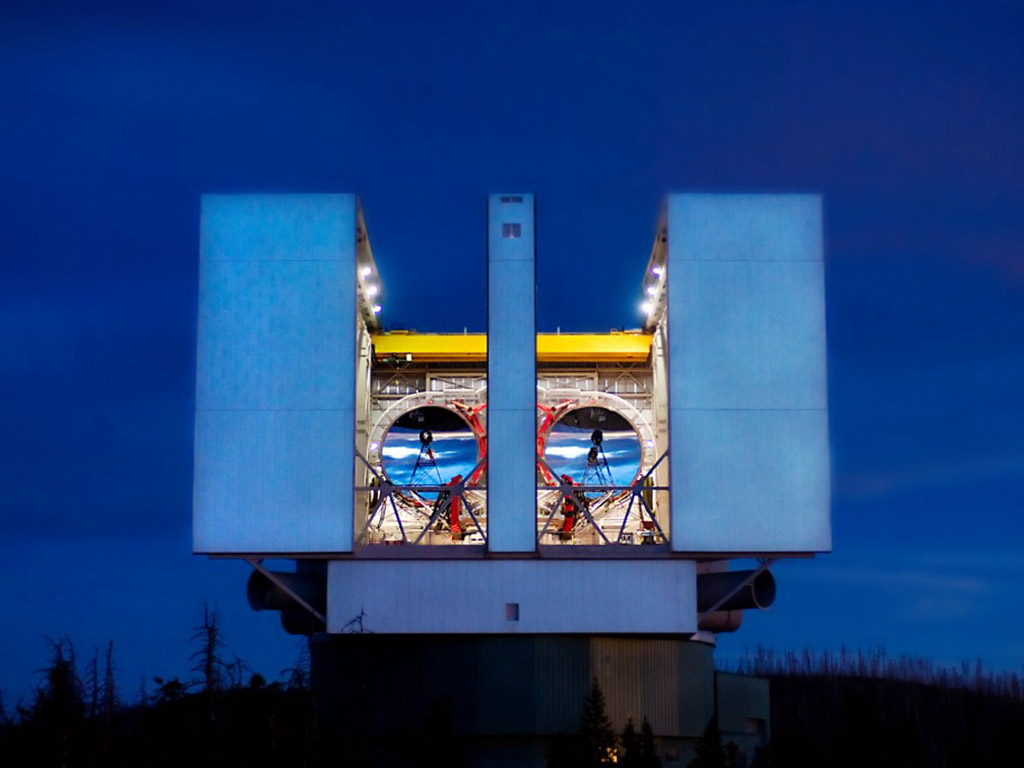

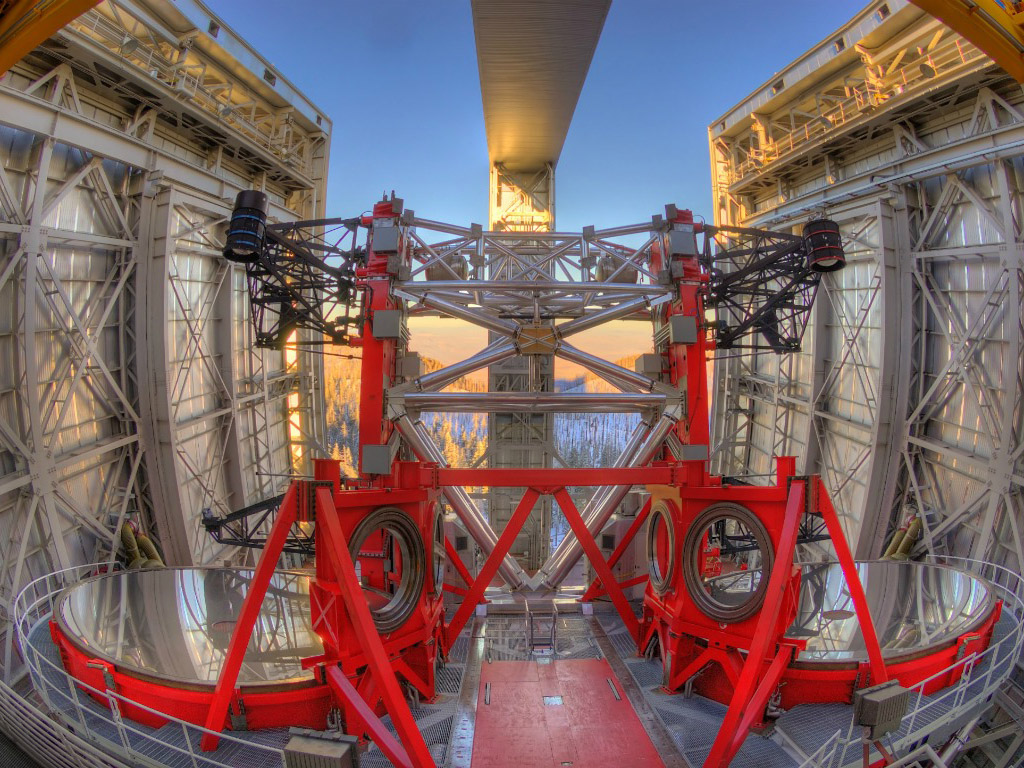

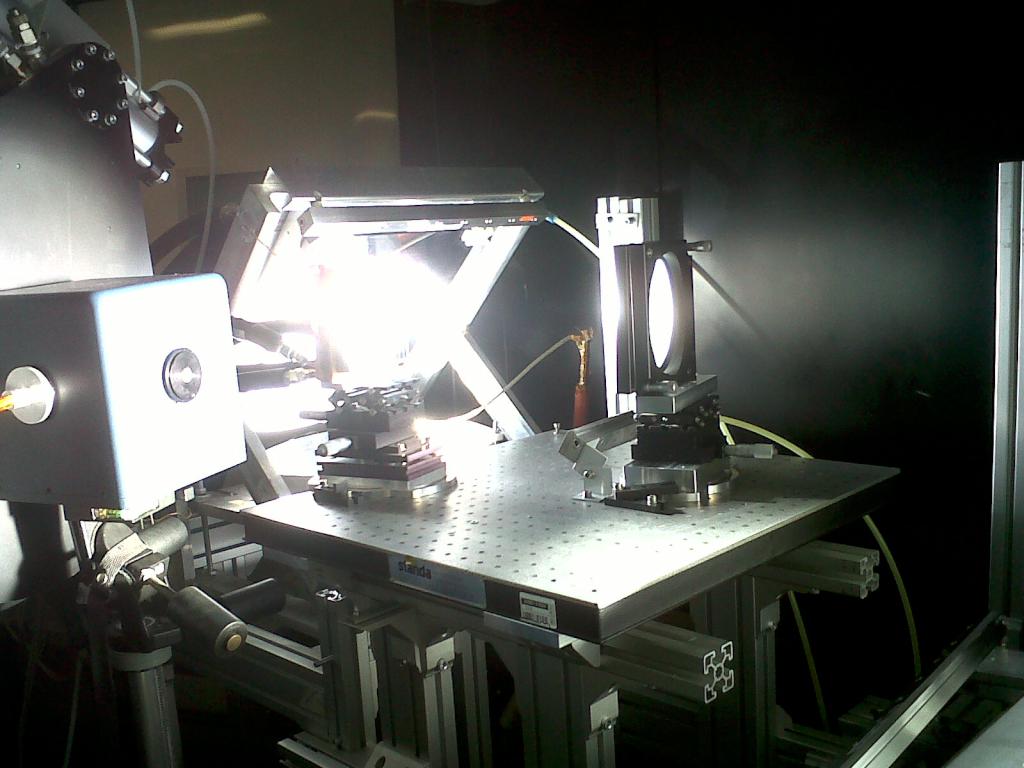

Designers are empirically studying the efficiency of the adopted solutions analyzing, among the various parameters monitored, erosion’s profiles of these surfaces based on the numbers of working hours of the engine. Usually, Hall-effect engine’s tests are carried out installing the device on a dynamometer and inserting all in a big vacuum chamber, in a way to reproduce the engine’s operative condition. These analyses require the interruption of the thin air - which is known as breaking of the void – the extraction of the dynamometer and the dismantling of the engine, which is then positioned on a system suitable for a dimensional measuring. This whole process is extremely time consuming: for example it usually takes between two and three days to replicate the void necessary for the execution of these tests. In addition to this, it is also necessary to add the time for the assembly and dismantling of both the dynamometer’s engine and the tool used for measuring and the time for the measure itself.

Technology

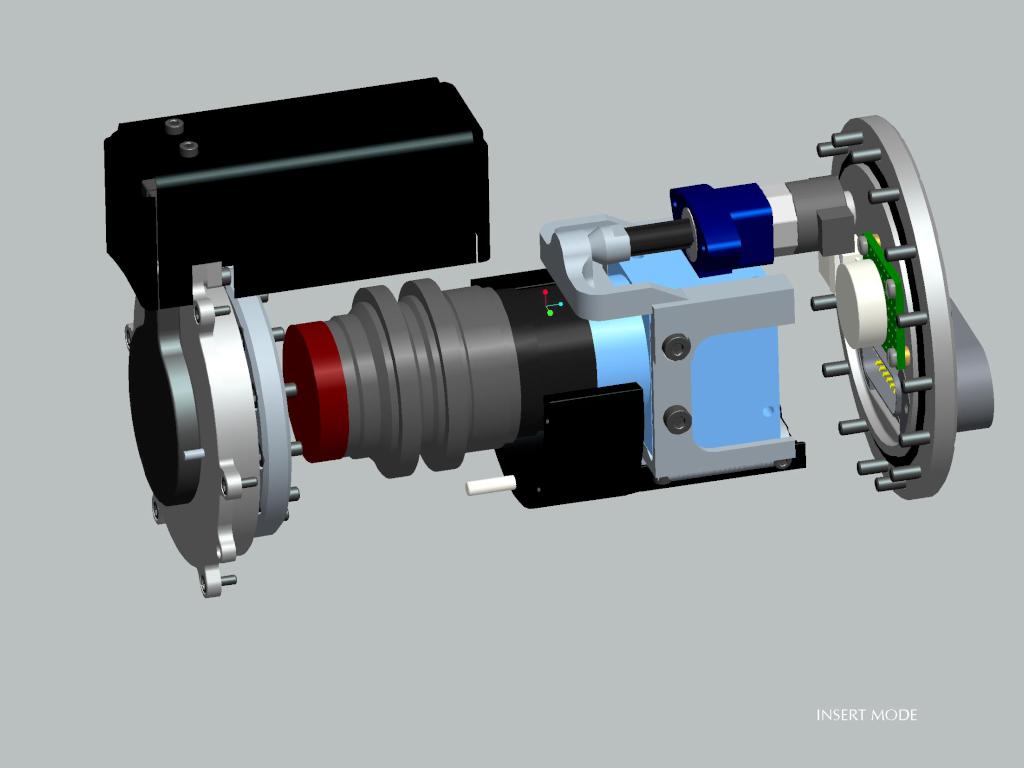

The need to limit development period of Hall-effect thrusters requires the realization of a particular system, which measures the erosion occurred. The most important condition that needs to be satisfied is the possibility for the instrument to measure things without having to take apart the motor from the load cell and to extract it from the vacuum chamber.

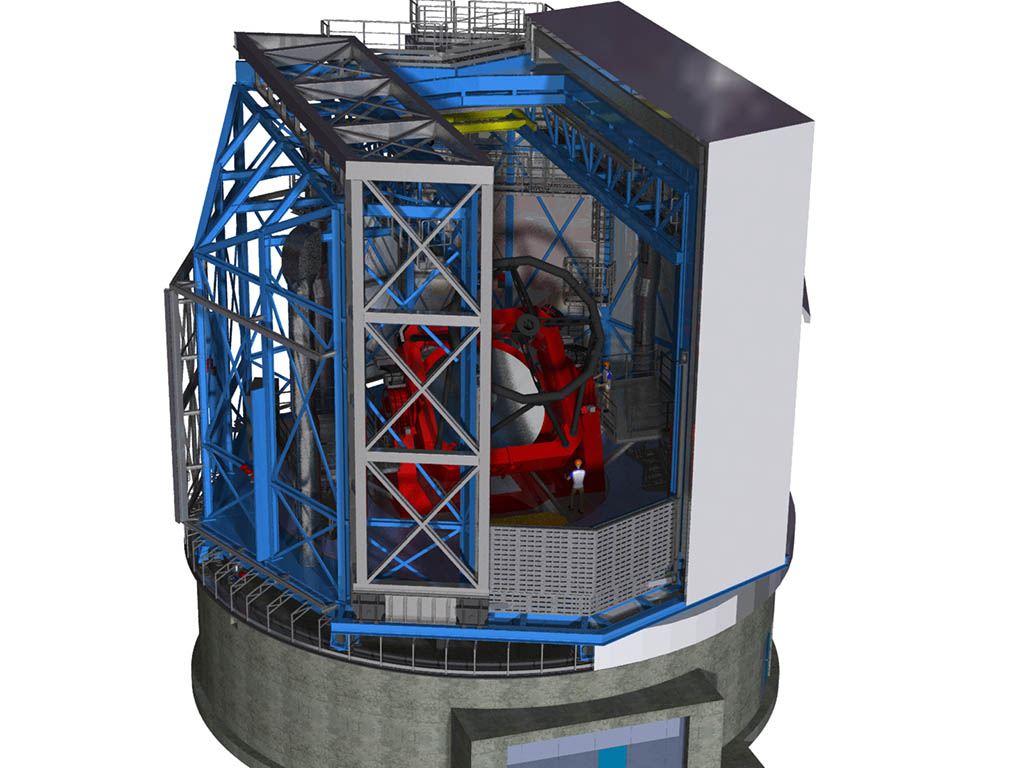

The instrument had to adapt to all of the in-use vacuum chambers and to be adaptable to other unladed chambers that may be added to the already existing instrumentation. All these operational requirements combined together led to the definition of an instrument that can be installed inside the vacuum chambers, equipped with a self-calibration system for the compensation of the misalignments, adaptable to different sizes of Hall-effect thrusters.

Link alla pagina ufficiale

http://www.esa.int/Our_Activities/Space_Engineering_Technology/Propulsion_Laboratory