E-ELT - European Extremely Large Telescope

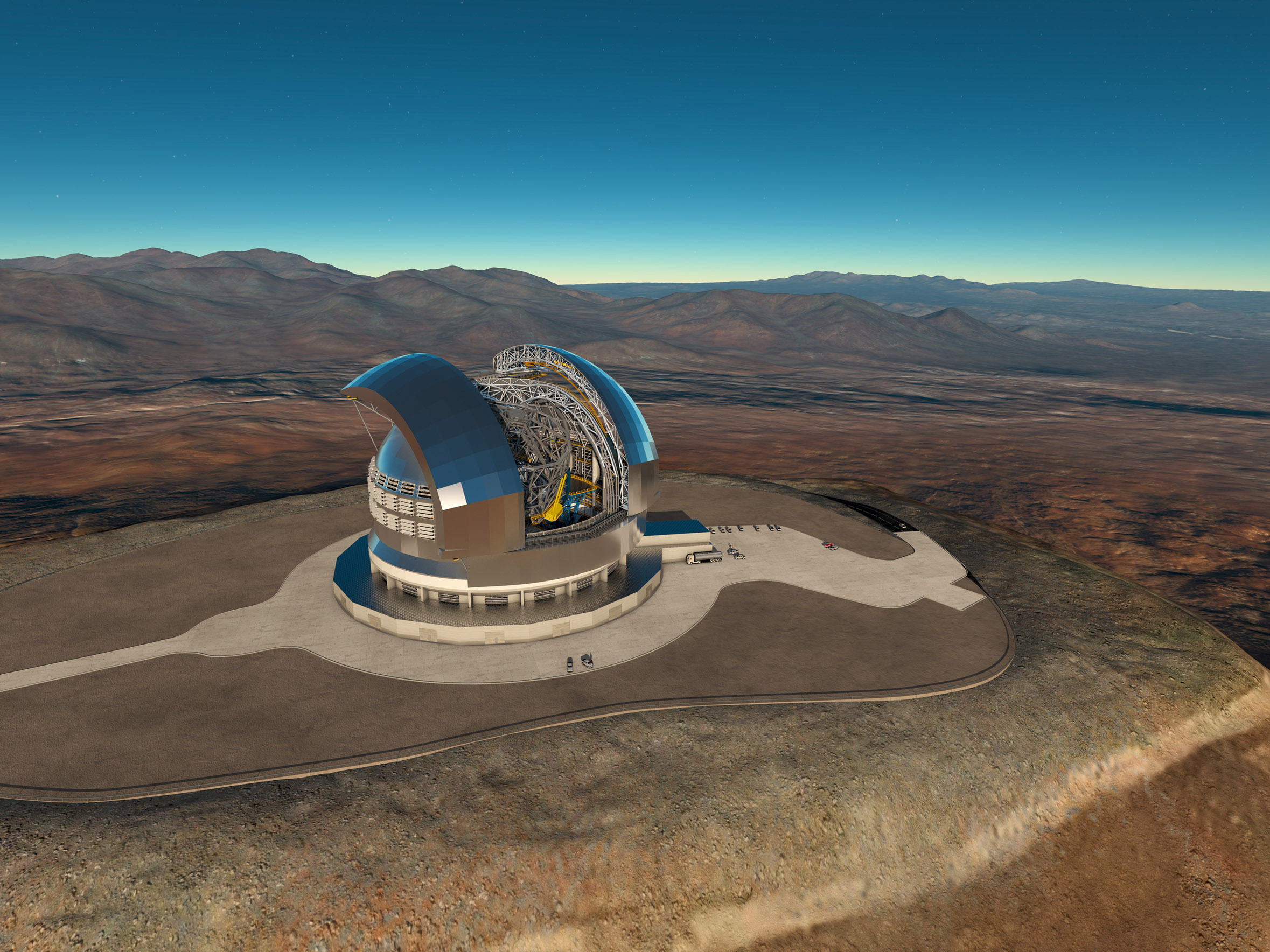

Site: Cerro Armazones - Chile

State: Under Design and Construction

Activities:

Detail Design, Manufacturing, Pre-Assembly in Europe, Packing &Transport, Erection on Site, Commissioning and Testing activities

Date: 2009 - under construction

Client: ESO - European Southern Observatory

Category: astronomy

Credits: ESO courtesy/EIE GROUP

E-ELT - European Extremely Large Telescope

400 years ago, Galileo Galilei built the first 37mm lens telescope and went down in history thanks to his discoveries in the astronomical field. Nowadays, both the Italian and the European industries are working together to design the greatest telescope of all times: ELT – Extremely Large Telescope by ESO – European Southern Observatory, which will have a 39m diameter primary mirror.

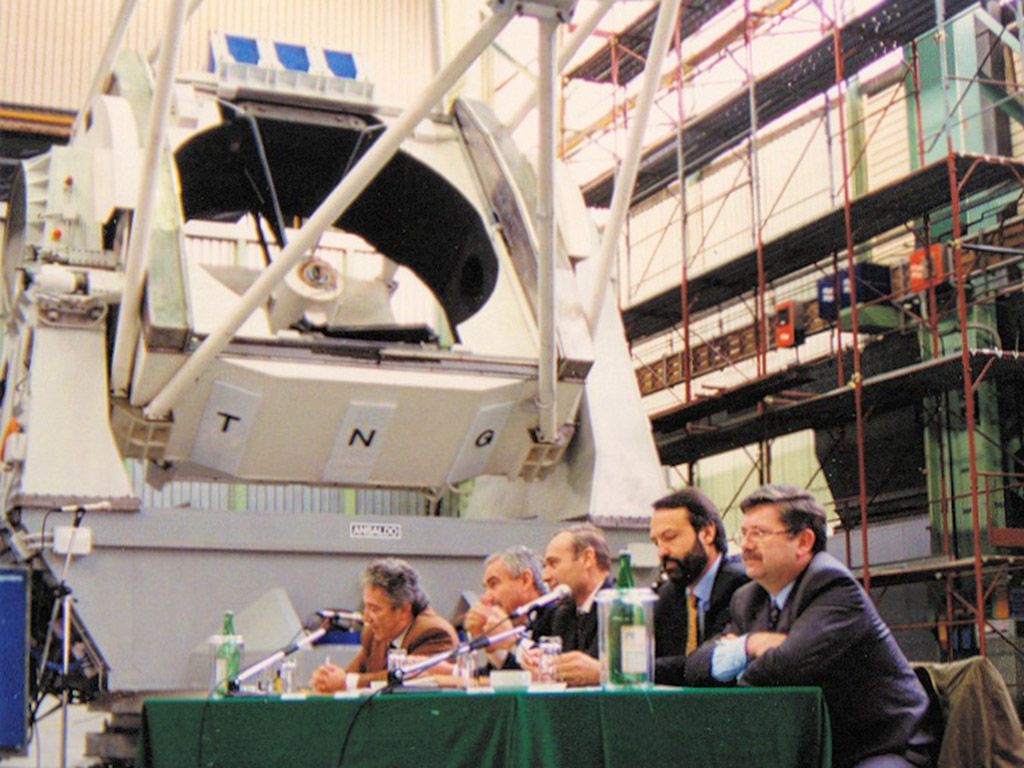

EIE has been working beside ESO since 2007 in the study and definition of the biggest telescope in the world. We developed Feasibility studies, Conceptual Design studies for the telescope as well as FEED (Front End Engineering Design) studies for the characterisation of the Dome and Telescope Main Structure, initially for a 42m diameter primary mirror telescope and subsequently for the final version, a 39m diameter telescope. Seven years later, in 2014, ESO opened the invitation to tender for the “Design, Manufacture, Transport, Construction, On-Site Assembly and Verification of the Dome and Main Structure of the European Extremely Large Telescope".

On February 5, 2016, ESO’s Financial Committee authorized ESO to enter into final discussion with the ACe Consortium, consisting of the industrial companies Astaldi Spa, Cimolai Spa, with EIE GROUP Srl nominated as sub-contractor.

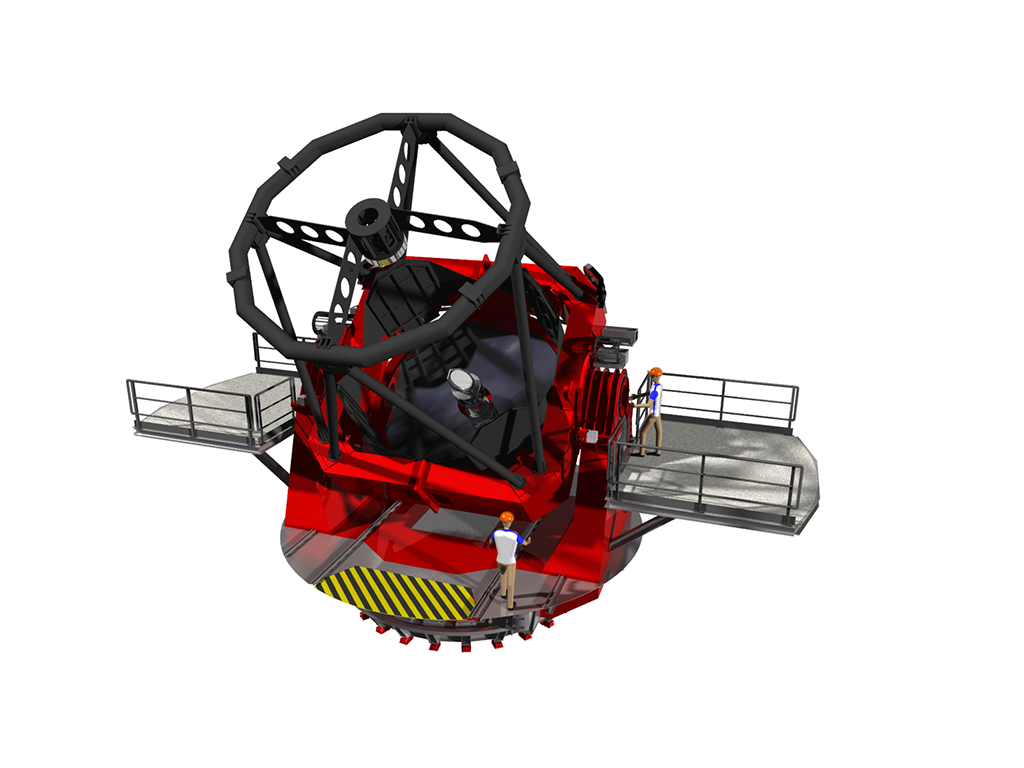

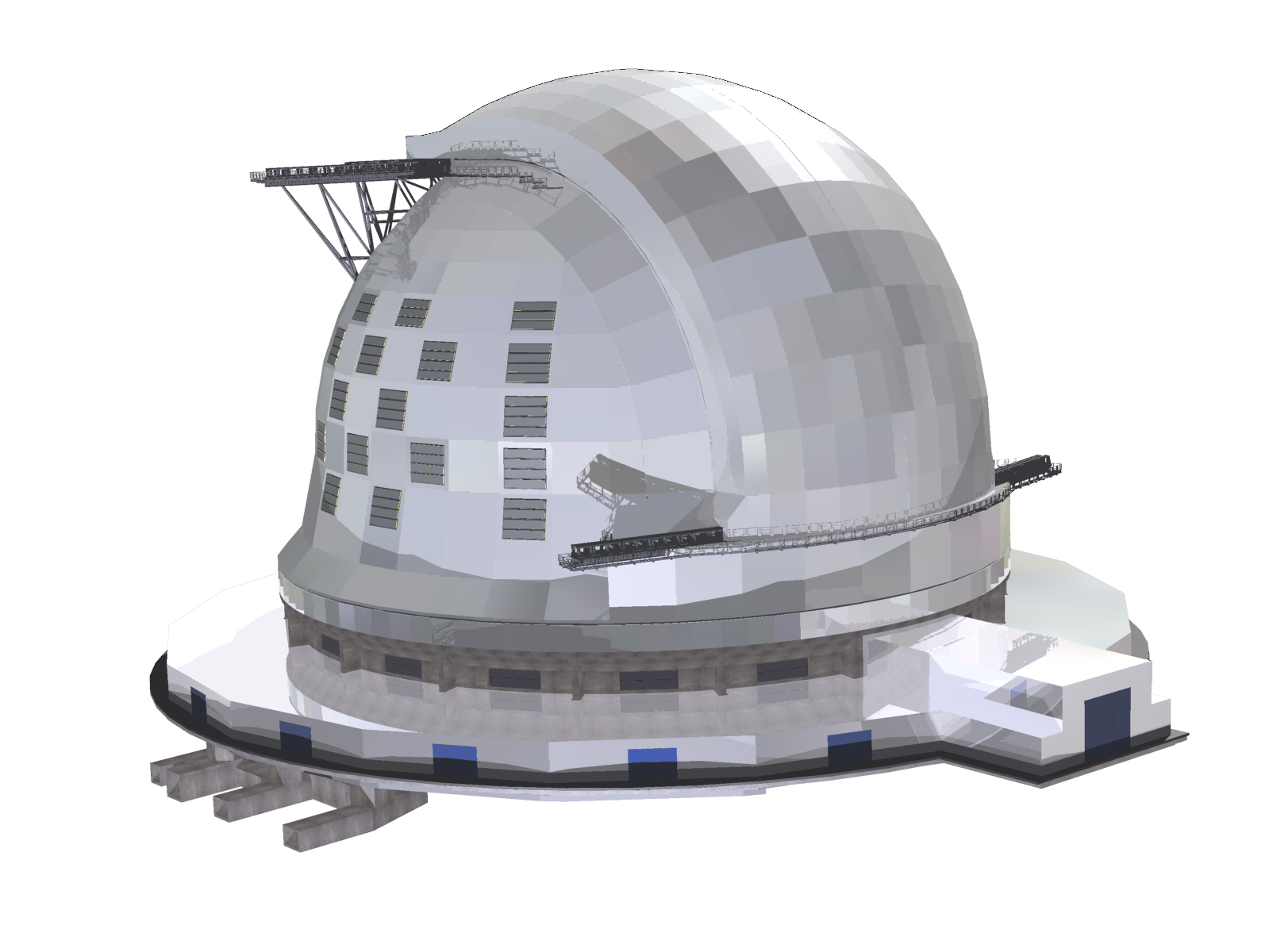

ELT will be a revolutionary optical instrument for medium and near infrared observations; the 39m -diameter primary mirror will gather up to 13 times more light than the large optical telescopes operating today and it will give images 16 times clearer than those obtained from the space telescope Hubble. ELT will definitely be the most powerful telescope in the world, equipped with ground-breaking technologies and innovative systems.

The ELT telescope is an extraordinary scientific and technological challenge that will revolutionize our perception of the Universe, just as Galileo Galilei’s telescope did 400 years ago.

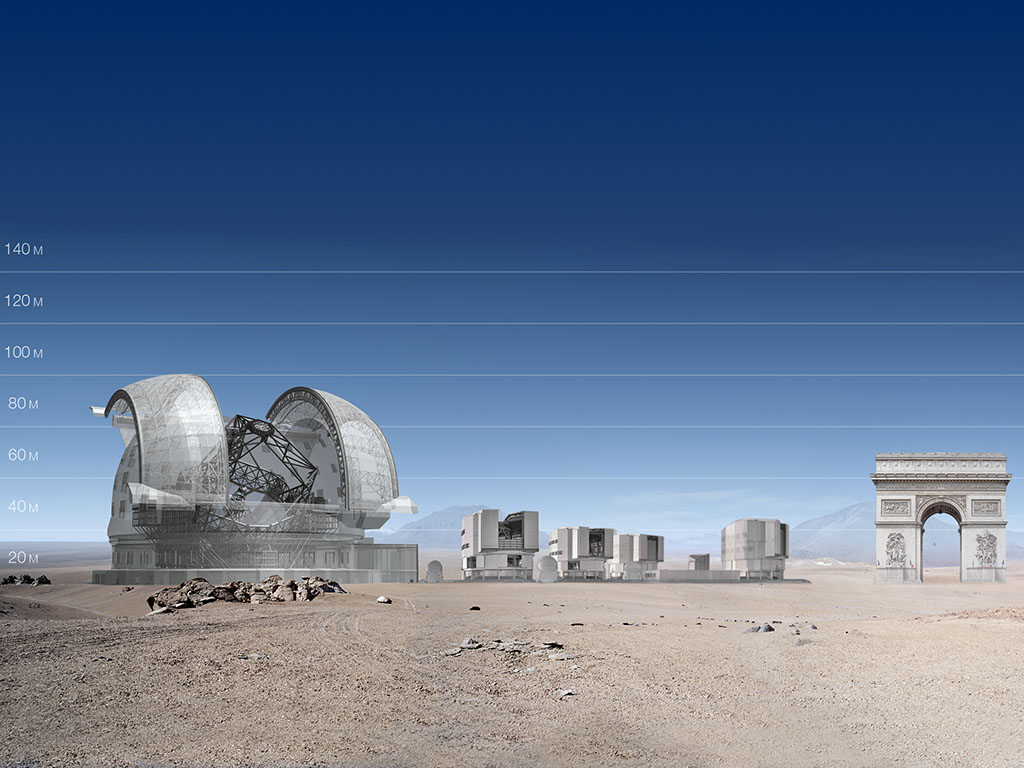

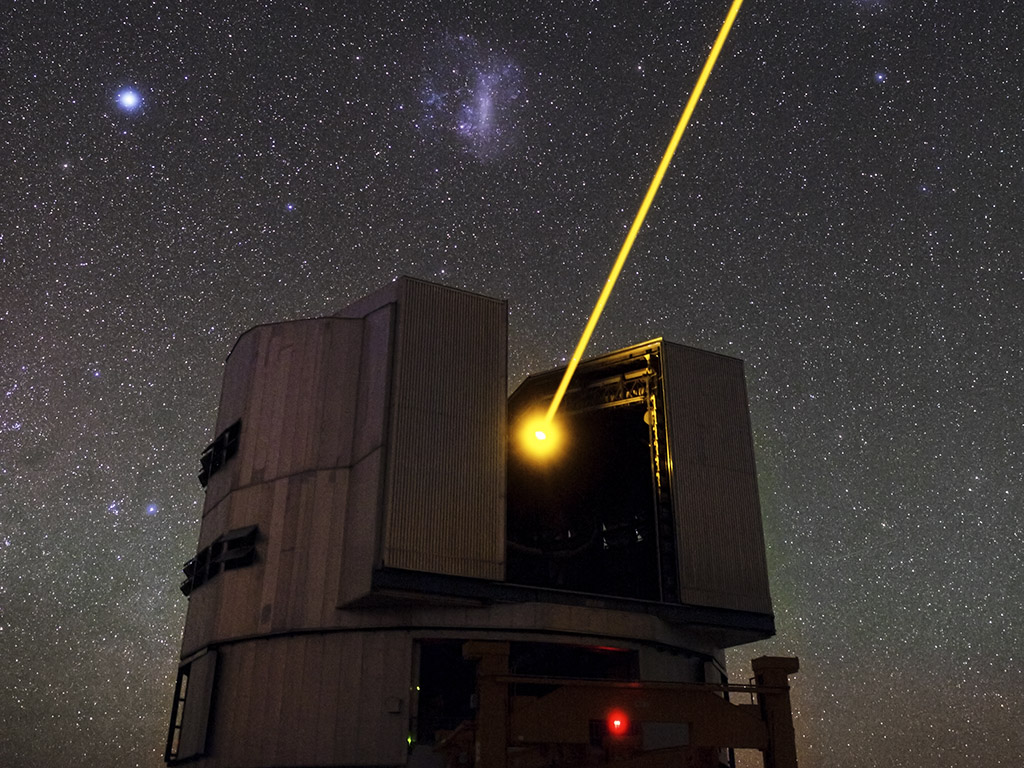

ELT will be installed in Chile on the Cerro Armazones in the central part of the Atacama Desert, 130 km south of Antofagasta, at 3.046m above the sea level.

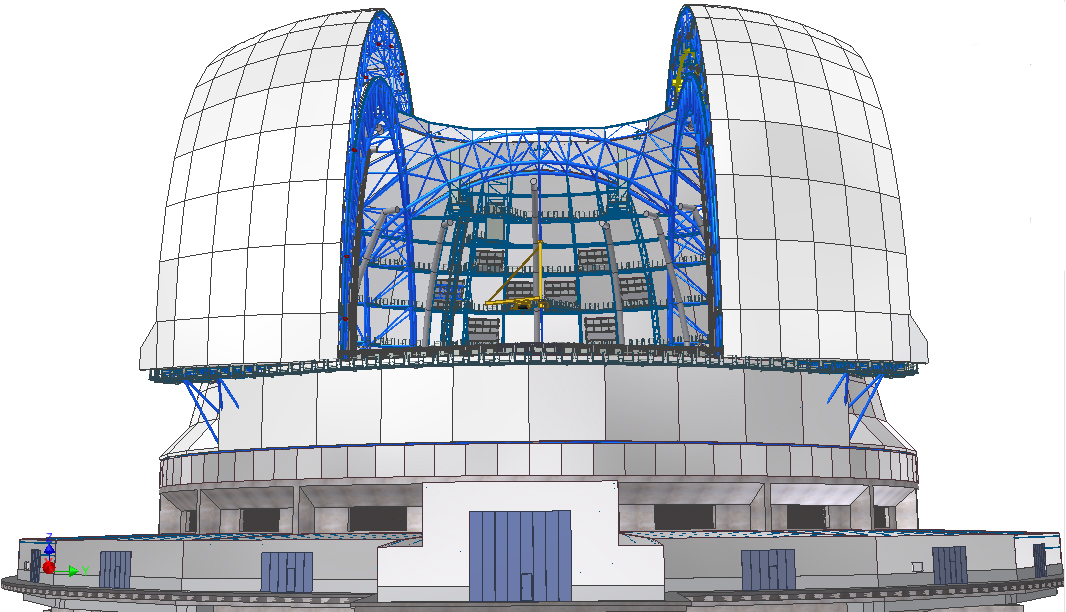

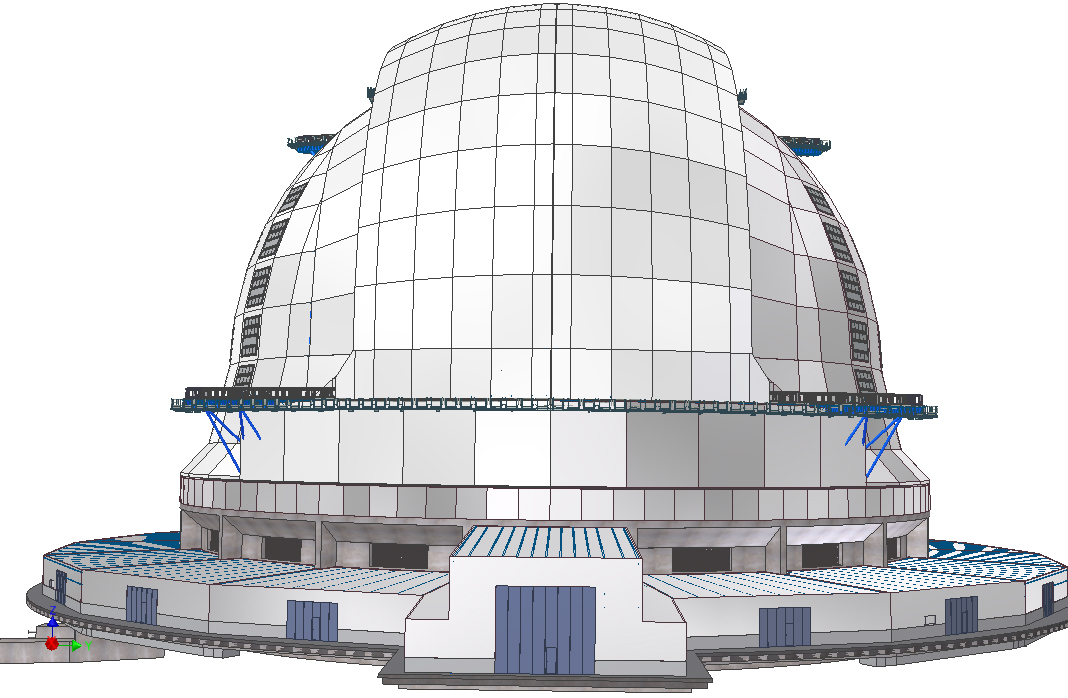

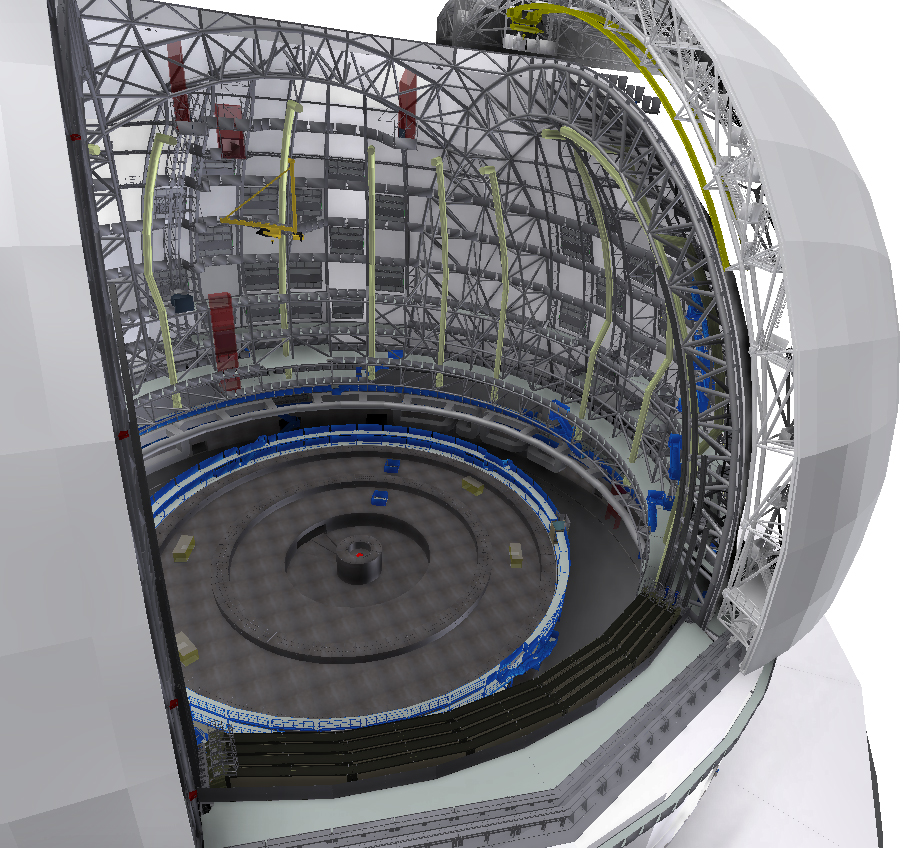

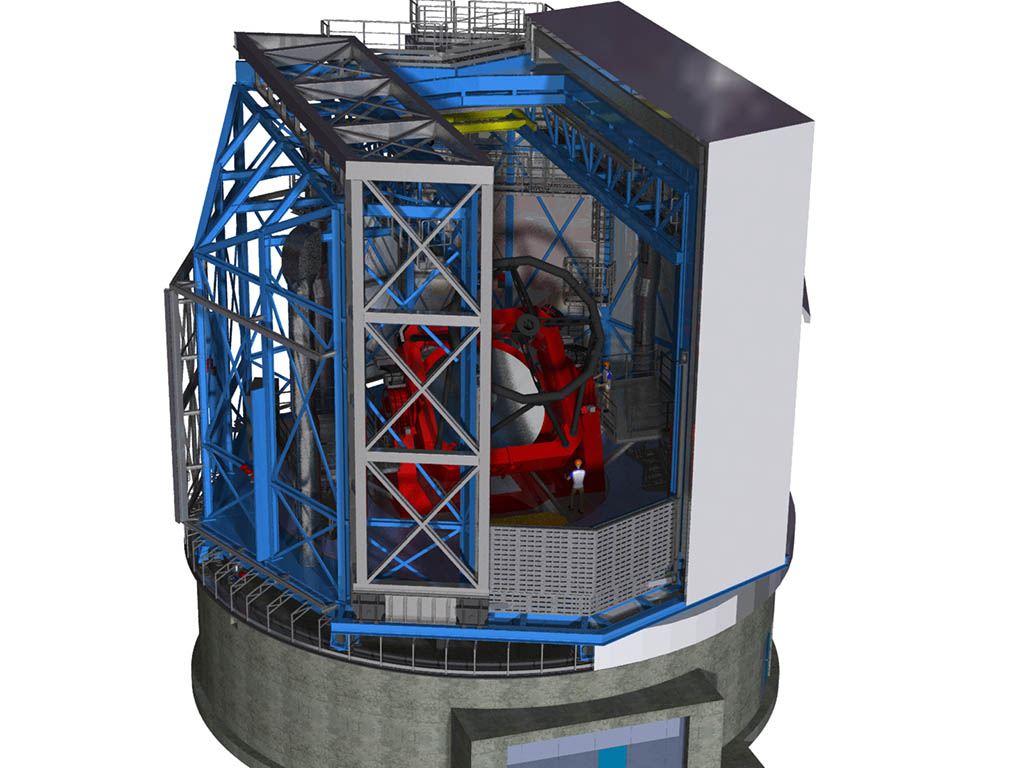

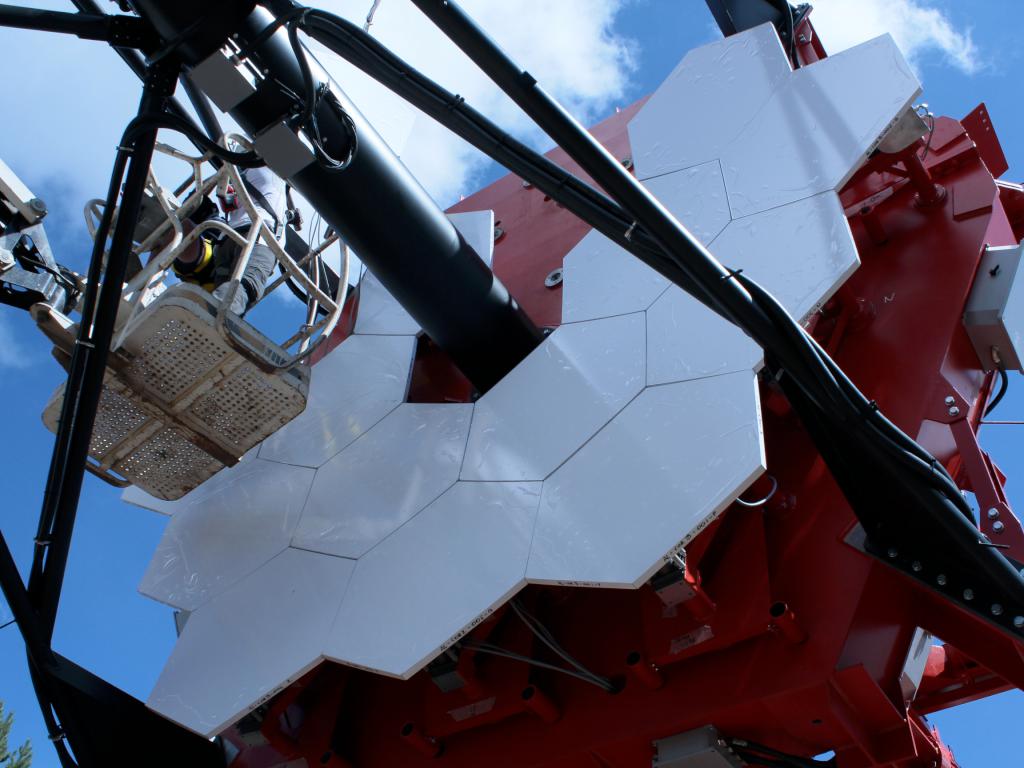

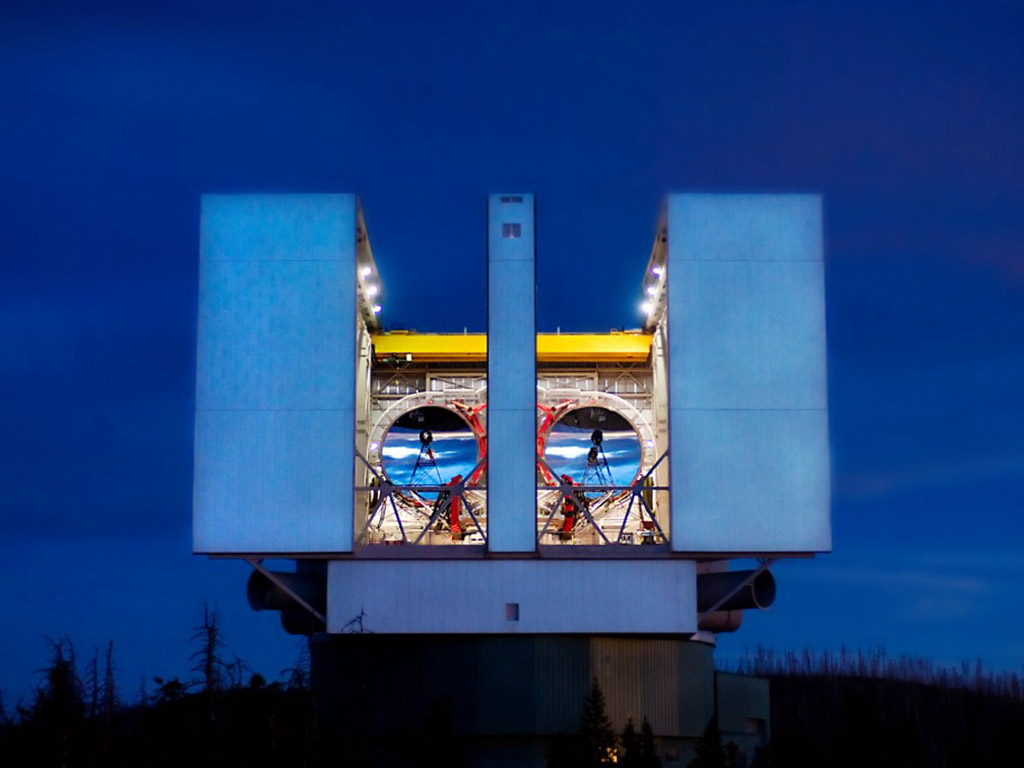

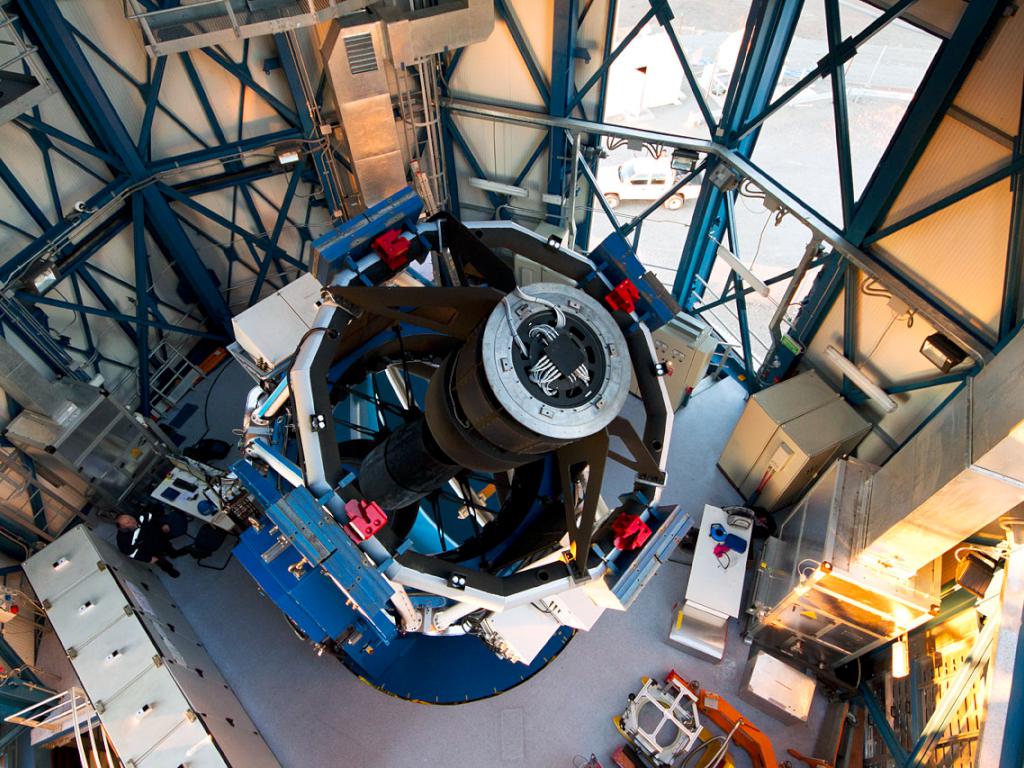

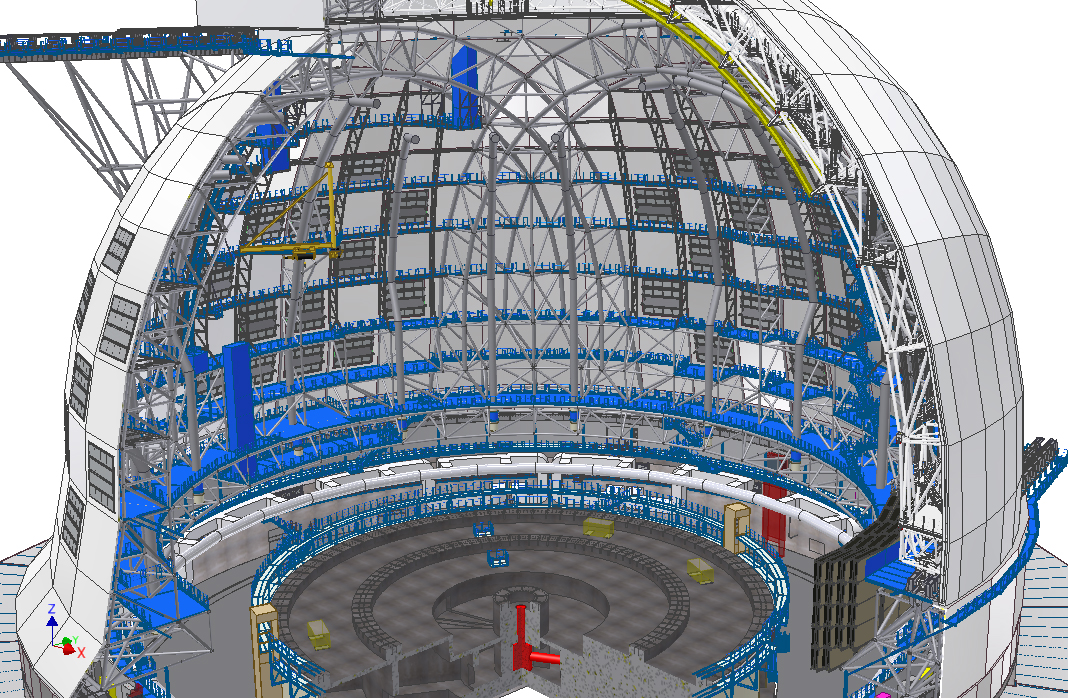

The ELT telescope represents an extraordinary set of scientific and technological challenges. In order to have a perception of its greatness, just think that the telescope will be 65m high and will weigh 3500t (including mechanisms), with a 39m-diameter primary mirror made of 798 hexagonal segments of 1.4m in diameter and a thickness of 5cm each. The rotating dome will be 95m in diameter, 80m high and will weigh around 4980 t (excluding auxiliary buildings and civil works).

EIE GROUP is the only company in the world that was awarded by ESO the design for both the telescope and its dome.

The design of ELT started in 2007. Studies and analyses were made in the beginning in order to improve, optimize and verify the concept and the estimated costs. After that, Front-End Engineering & Design Study were taken into consideration and in the end, constructive studies made it possible for ESO to issue the call for tender.

All of the activities began considering a 42m diameter mirror, however after a series of optimizations it was decided that the telescope would have been provided with a 39 m diameter mirror.

The possibility to work at the same time on both of them gave us the chance to develop its Engineering and Design detailed integrated system.

Specifically, the following main activities were developed:

- Feasibility studies and analyses

- Every operation analyses, maintenance and safety activities

- Activities concerning systems, design and production documentation to realize, as required in the call for tender, for the Dome and

the telescope main structure.

Managing such a complex, multi-disciplinary and systemic project needs an exceptionally high professionalism of the organizational structure, cutting-edge technologies and a solid expertise. This is because E-ELT is one of the most complex projects ever realized in astronomy.

Nevertheless, such a project is characterized not only by its technological and organizational complexity, but also by the remarkableness of the required performances. It is a set of conditions whose systematic interactions determine the final, successful result. This result is defined by the ability of meeting the requirements of the project in each of the development phases in order to guarantee success in its entirety.

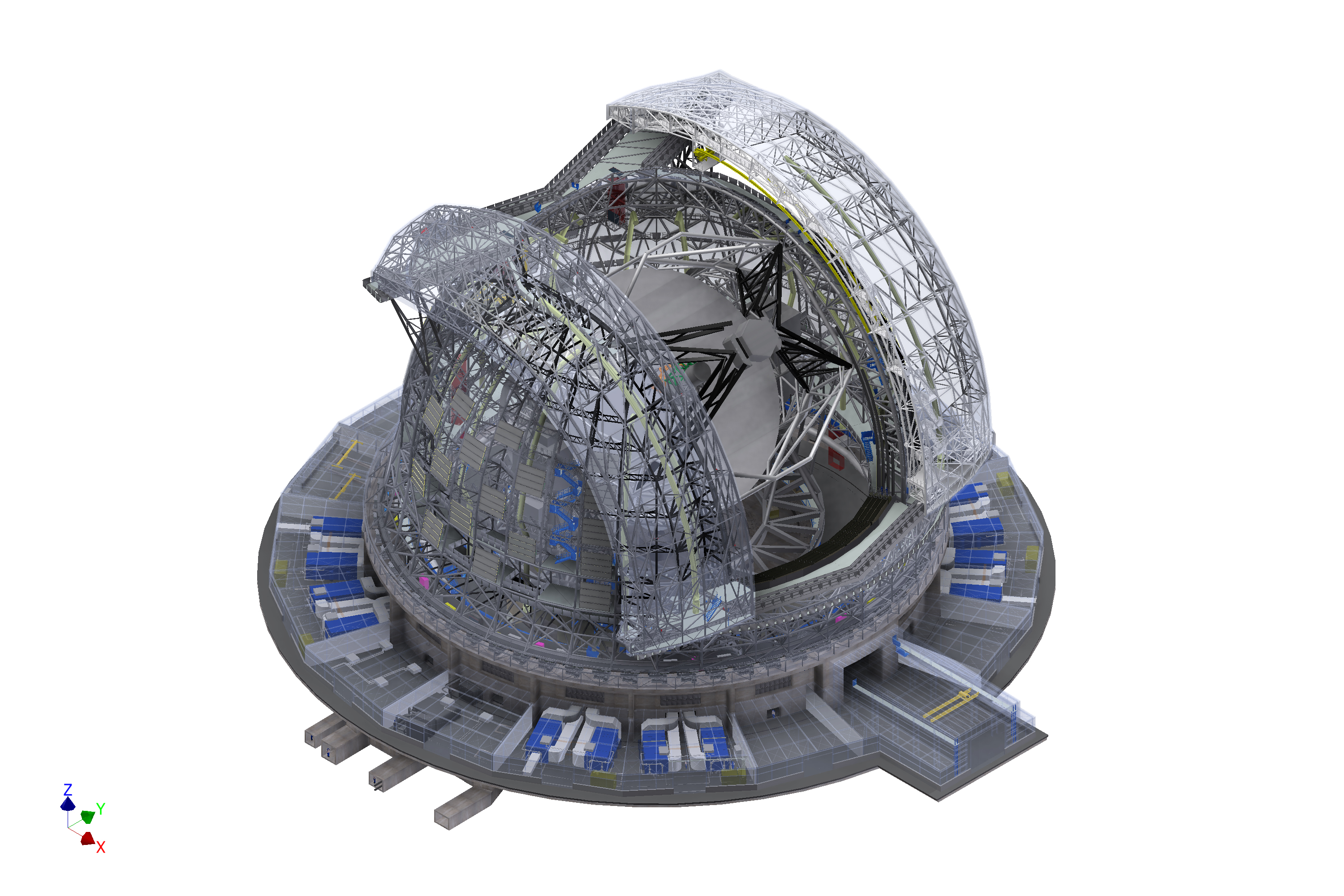

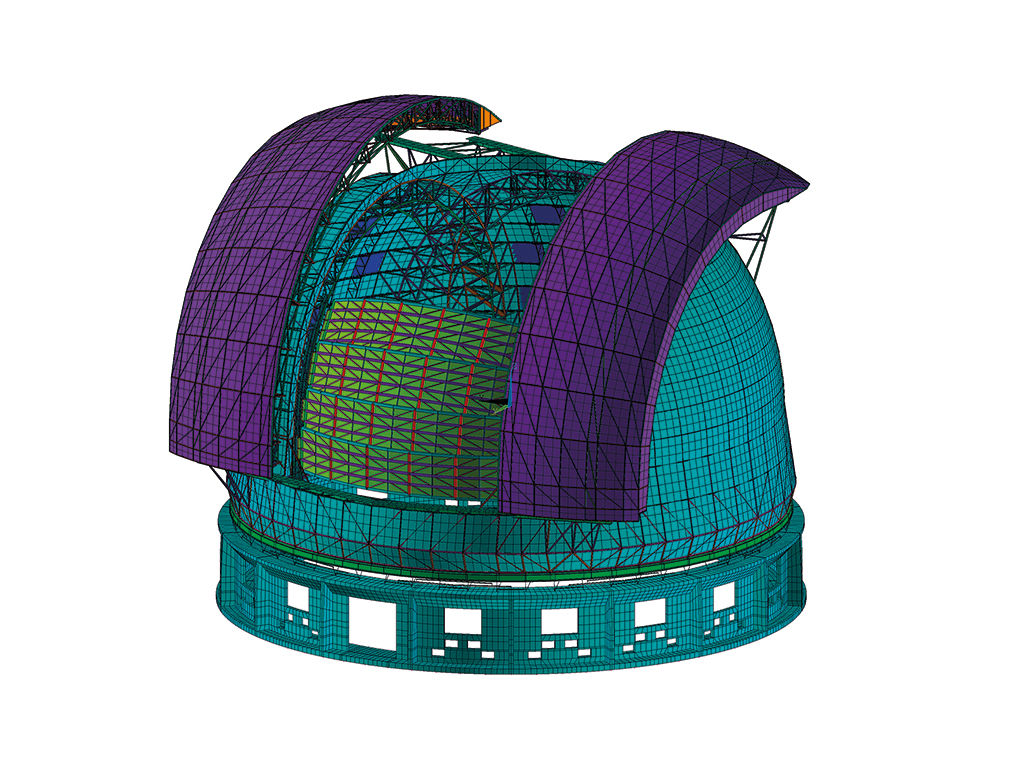

Considering just the ELT’s DOME, EIE GROUP has developed for ESO the following studies and analyses for the design of:

- Foundations;

- Cladding and Structures;

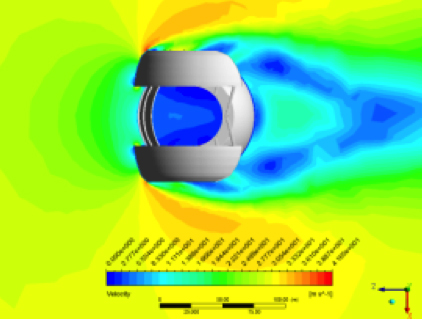

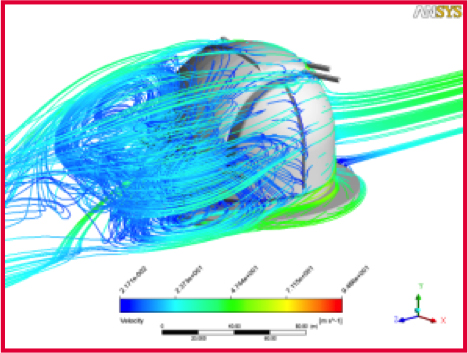

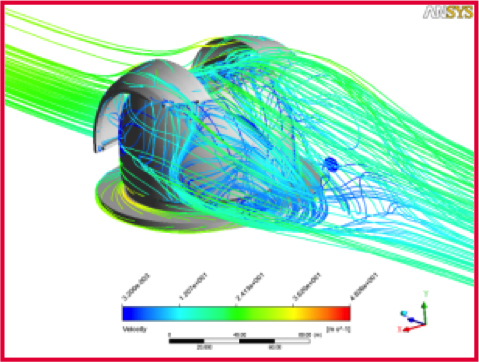

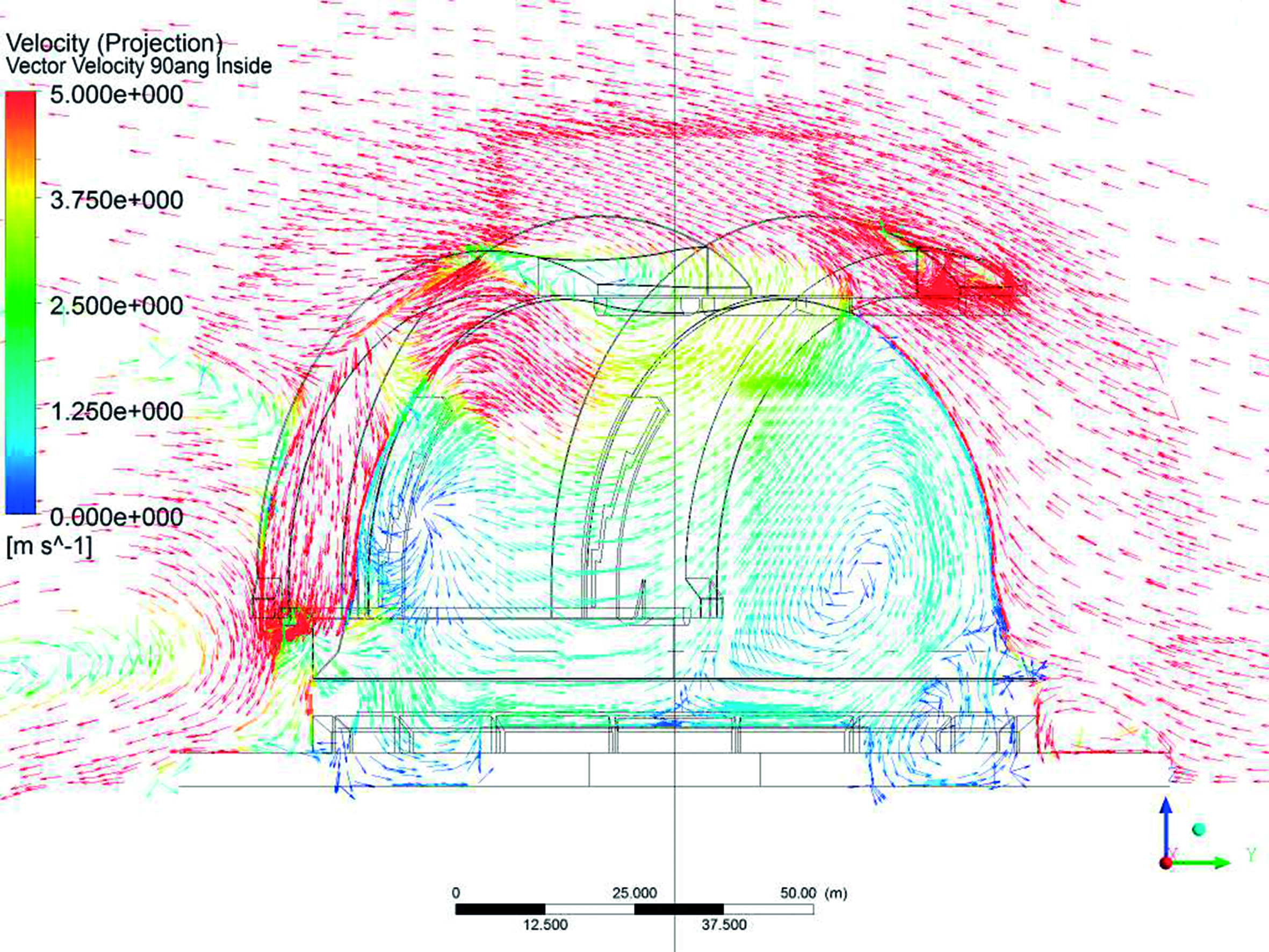

- Wind tests, CFD, FEA Analyses;

- Rotation Mechanisms;

- Dome Slit Doors;

- Louvers;

- Windscreen;

- Electrical Systems (power supply, fire alarm, etc.);

- Dome Control System;

- Thermal Control System;

- Auxiliary Buildings;

- Handling & Maintenance Equipment;

- Access Equipment;

- Seismic damping devices;

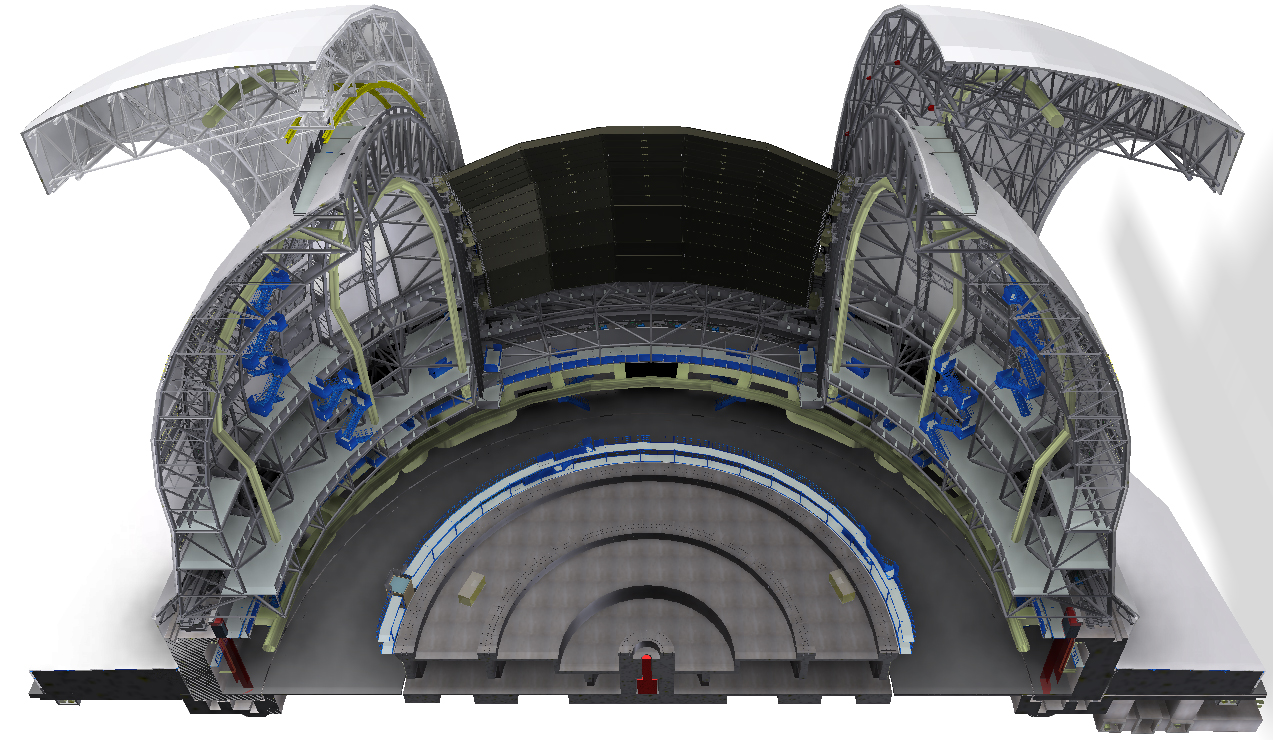

Dome’s design

THE FOUNDATIONS

EIE GROUP designed the foundations of the dome, the telescope and the auxiliary buildings:

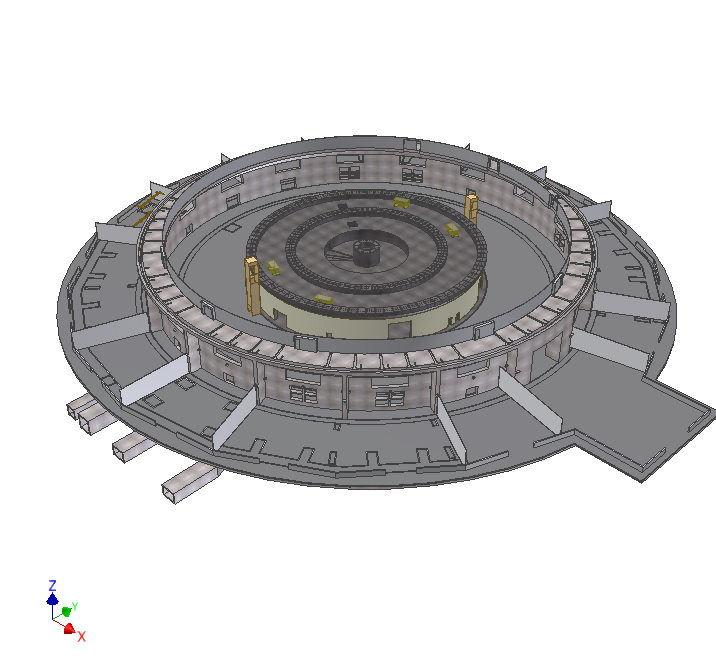

The dome’s foundations have a radially-symmetric structure, with a 12.40m high circular base and a thickness of 1m. This structure has a 79m internal diameter and a 92m external diameter.

The main characteristic of the Dome’s foundations is that they ensure the right stability of the base of the telescope even in case a strong earthquake occurs. For this reason, EIE GROUP decided to install the Hydrostatic Bearing Pad System, a series of devices that dampens the seismic shifts.

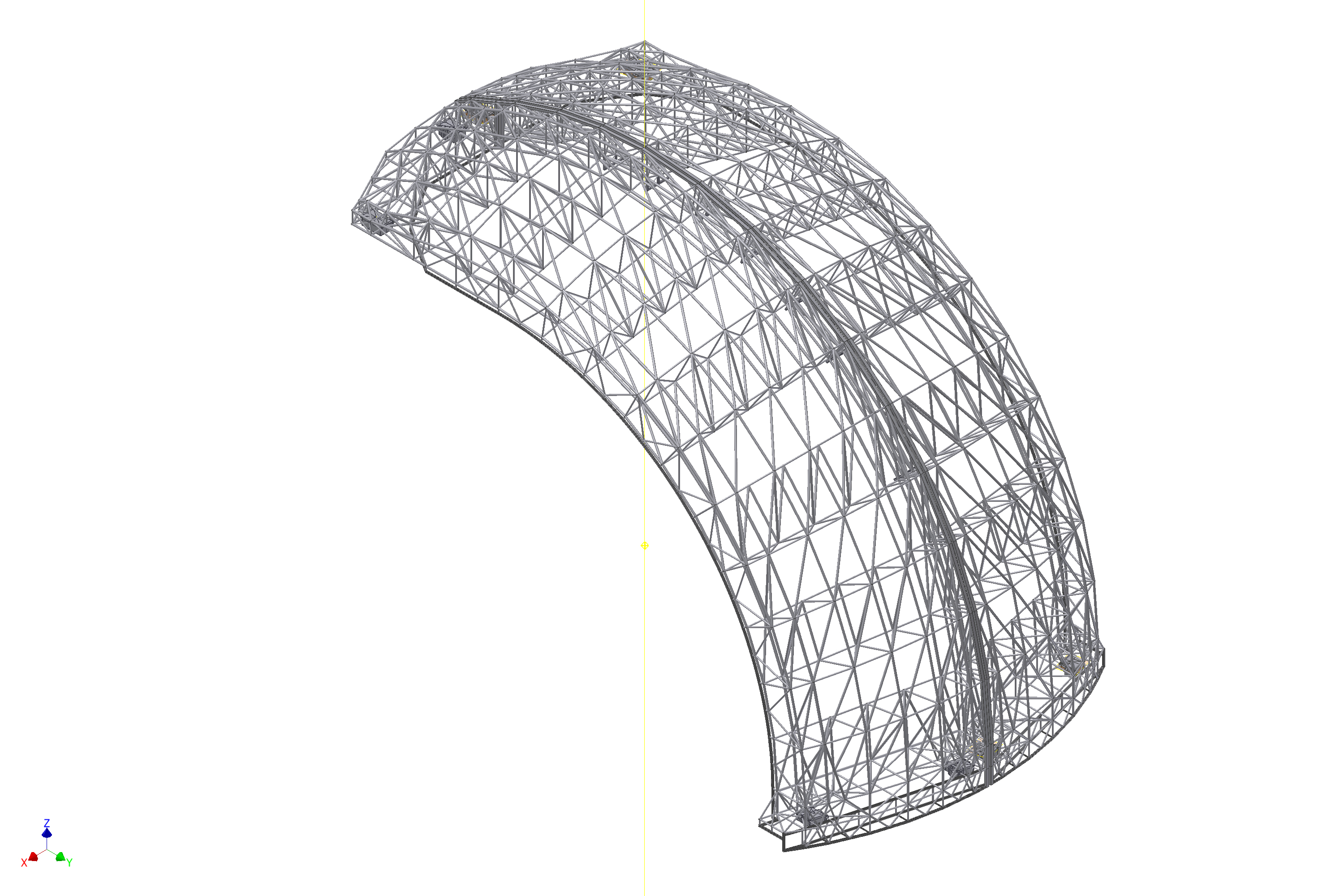

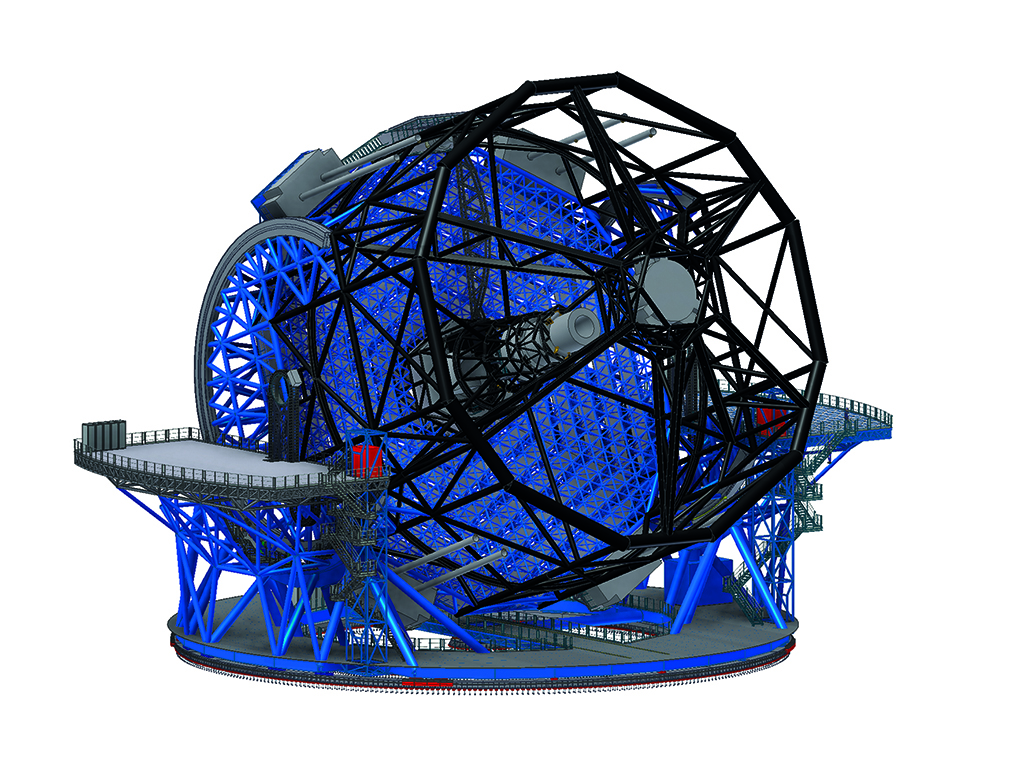

STEEL STRUCTURES AND CLADDING

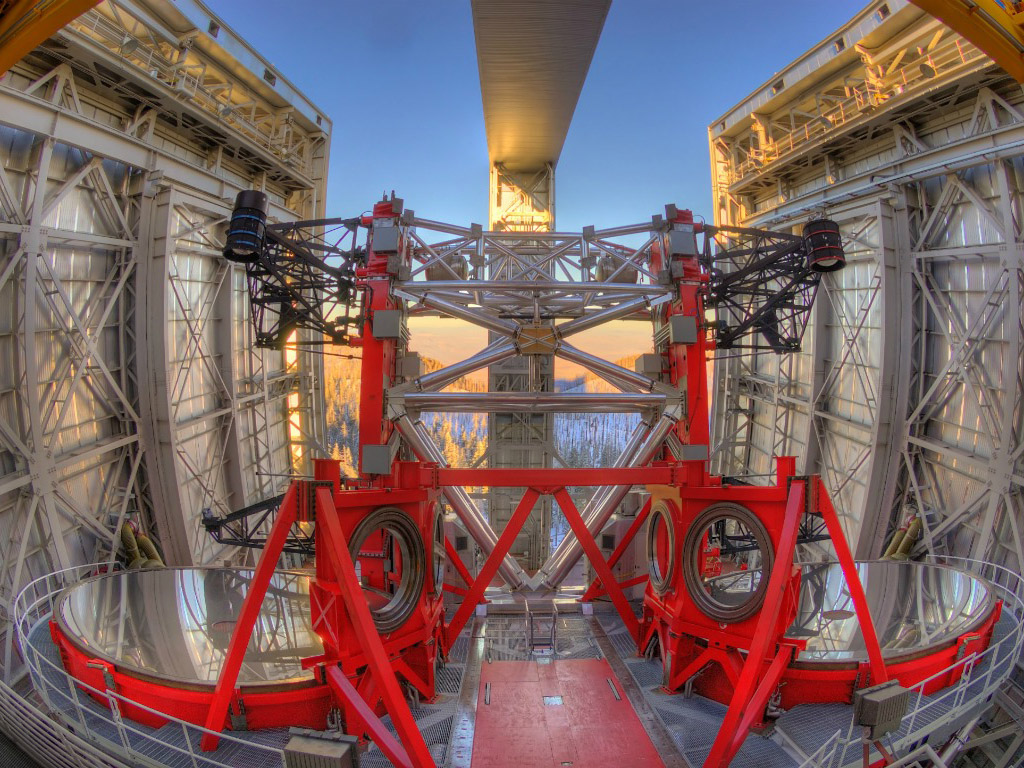

The idea of the steel structures of the dome is the result of EIE GROUP extensive designing experience, which our team put into practice in similar works, as the NTT, the VLTs, VST, VISTA, ALMA, LBT and many more.

The decisions made for the E-ELT took account of ESO’s performances requirements and limiting technical specifications.

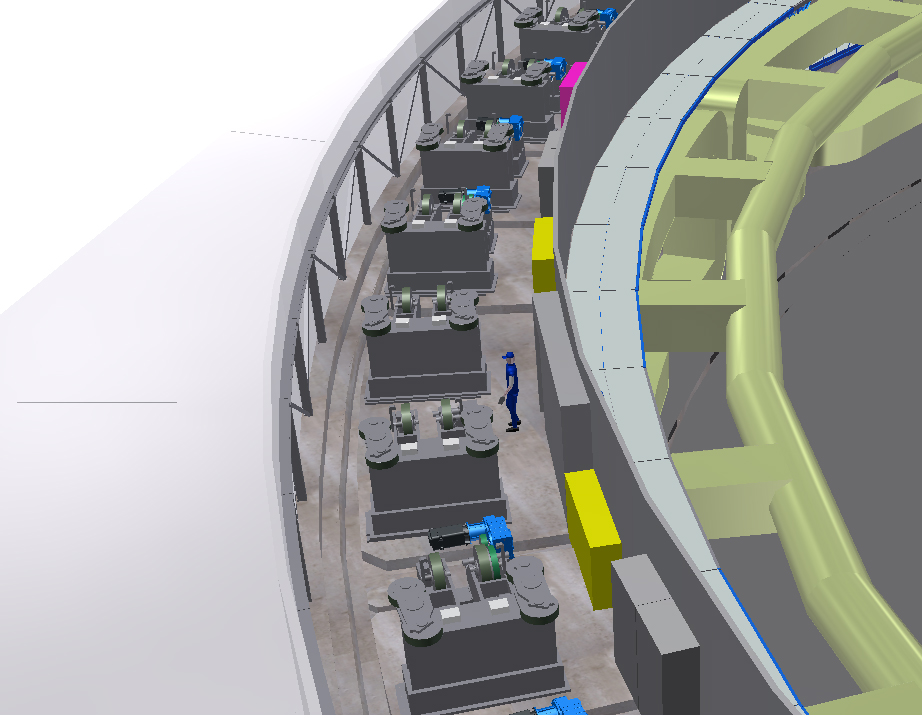

The ELT DOME is made of a complex steel structure whose purpose is to protect the telescope from bad weather and adverse climatic conditions. The telescope will be mounted in a rotating steel building, which will stand on a concrete pillar provided with a rail, on which 54 bogies and related mechanisms will be disposed.

The auxiliary buildings, including offices, meeting rooms and rooms specifically designed for technical and support activities, will all surround the main pillar.

We chose to take a systematic approach that made it possible to meet all the requirements of the projects during every designing phase, from the Preliminary Design Phase to the Detailed Design one.

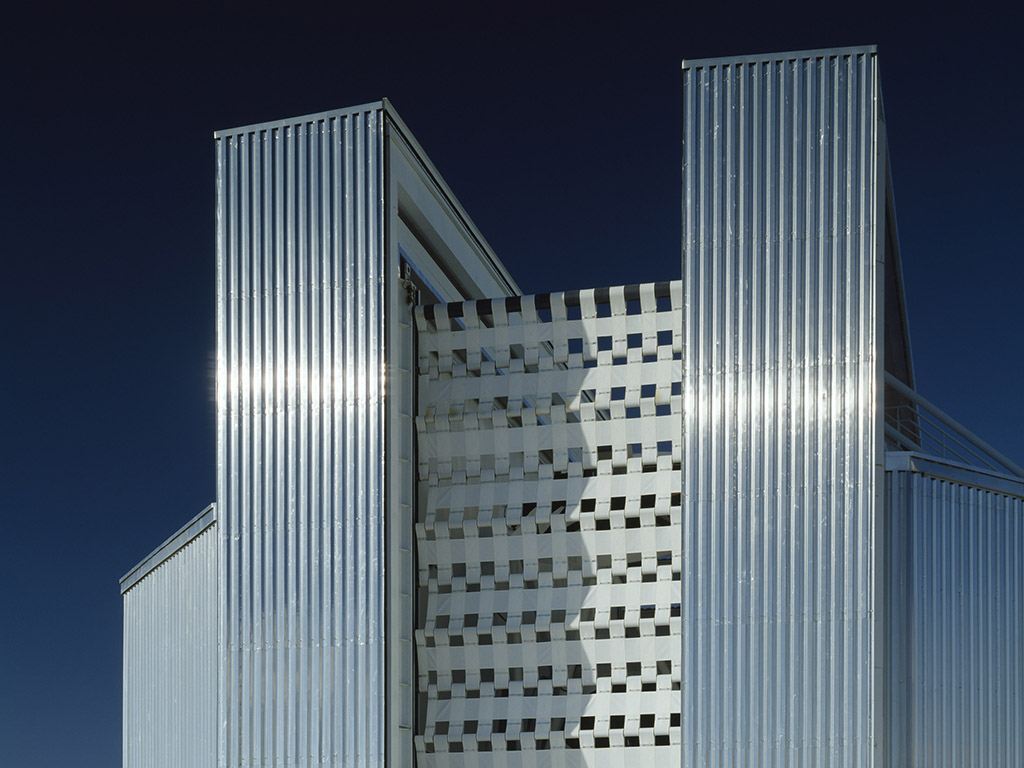

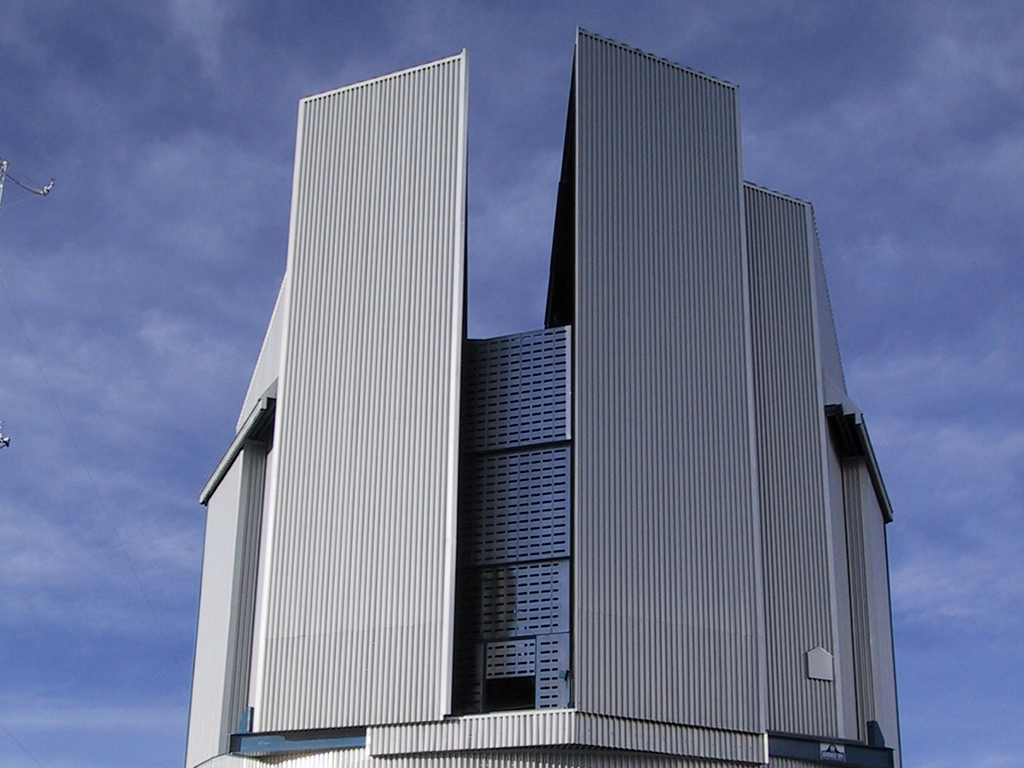

The cladding system of the dome serves as a windscreen, protecting the telescope from weather conditions. It was realized with corrugated case panels made of polyurethane, coated with metallic foils.

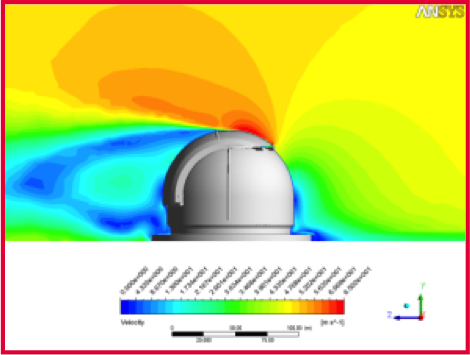

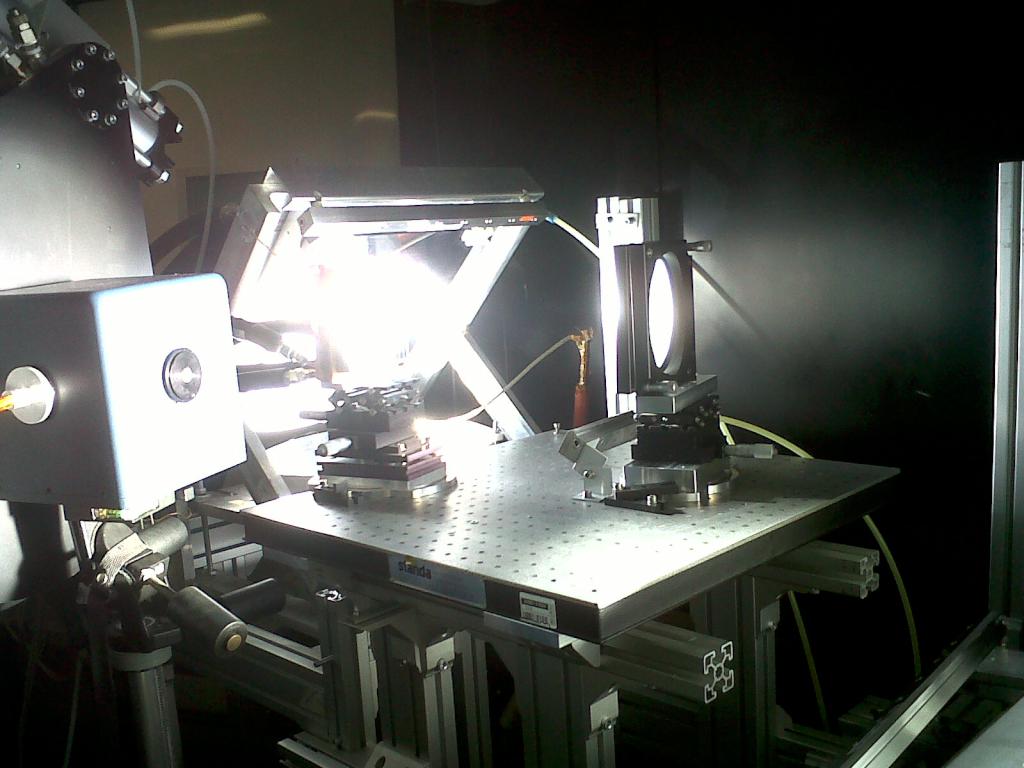

FEA, CFD, TEST, WIND ANALYSES

To verify the Dome’s structural strength, collapse resistance and possible structural deformations, different analyses were carried out, for instance FEA, CFD and wind tunnel tests.

ROTATION MECHANISMS

The Dome’s rotation mechanisms characterize the proper functioning of the telescope as well as the efficiency and duration of the observations.

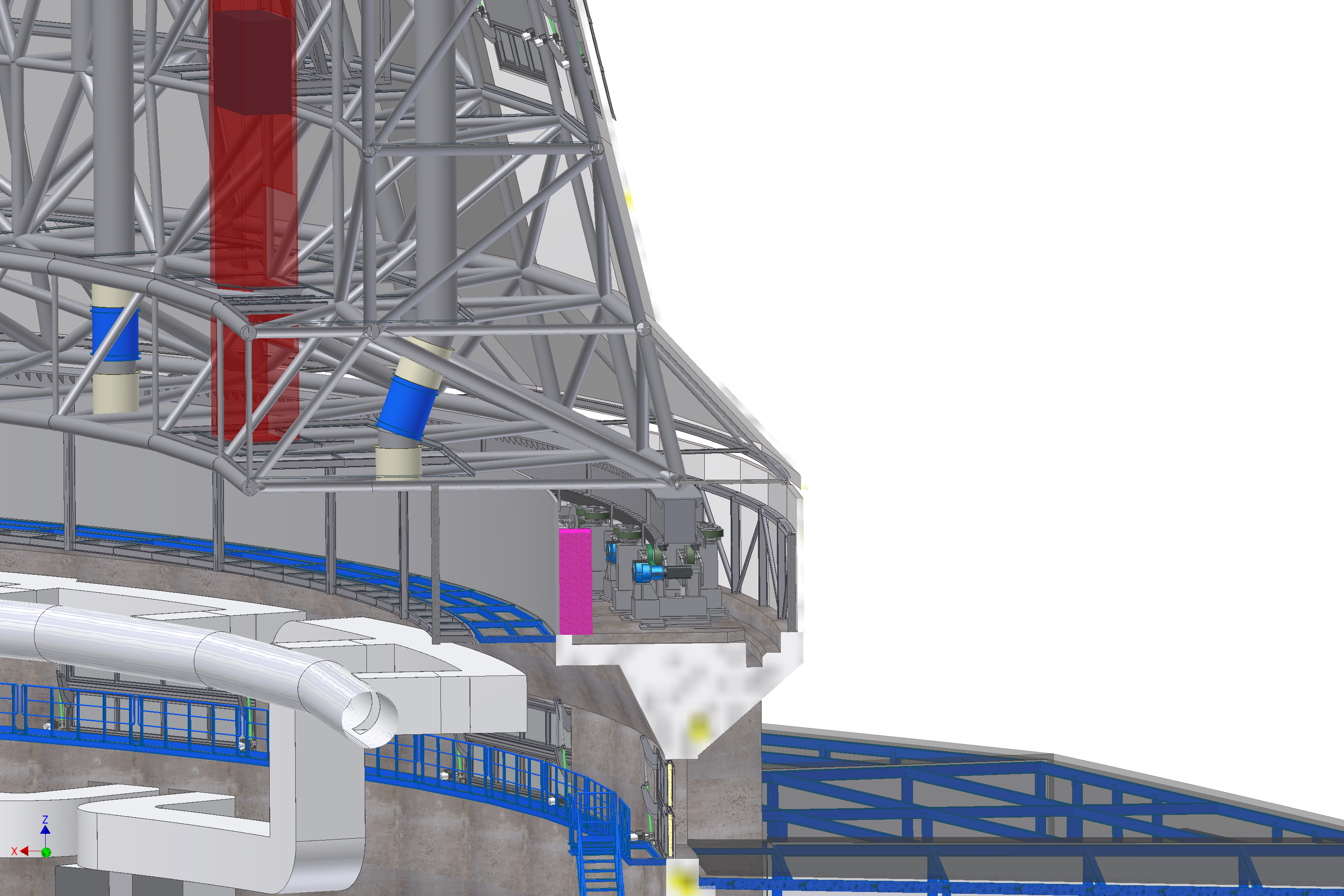

The rotation system consists of 54 bogies that are capable of bearing and containing lateral forces. They are placed on the pillar and run on a circular rail, and 40 of these are motorized. The remaining bogies are inert and equipped with encoders for controlling the rotation. This system ensures the rocking motion to be performed around the azimuth axis in both directions and it is independent from the telescope movements and the elevation level of the windscreen, as prescribed in the technical specifications.

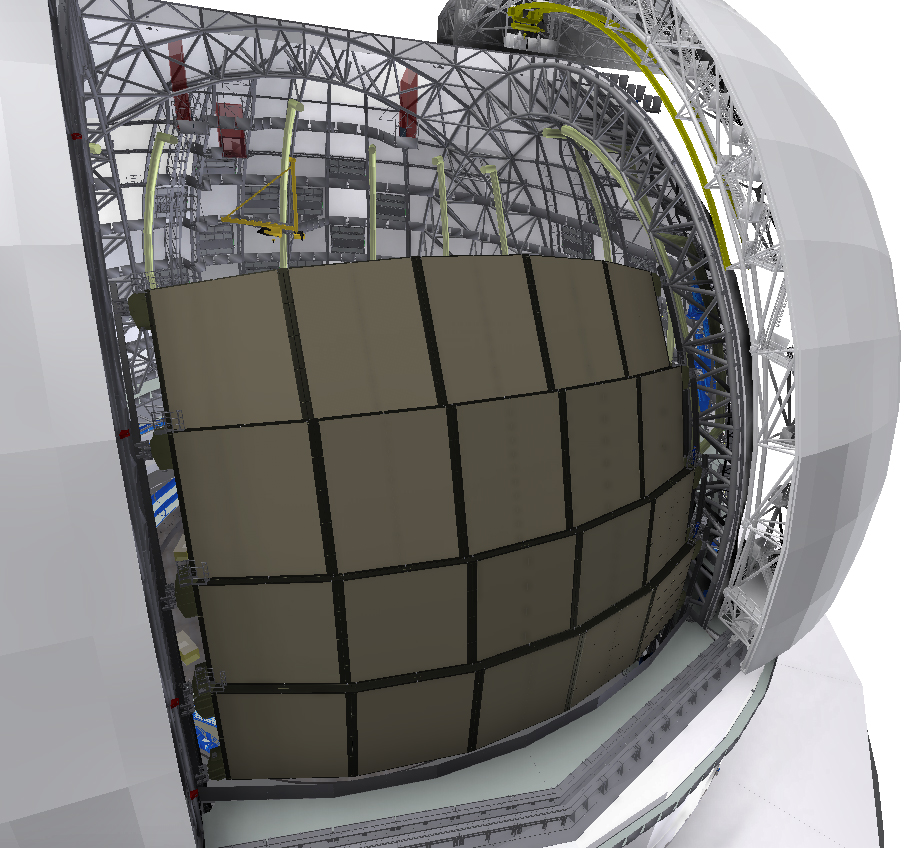

SLIDING DOORS

There are two large sliding doors mounted on ELT’s Dome. Both of them can be moved with the aid of 4 bogies that run along the guidelines placed around the circumference of the building. A system of inflatable lining prevents water leakages, while a locking-pin system guarantees the closing movement. In addition to the above-mentioned systems, a bumpers system prevents overloads in emergency cases.

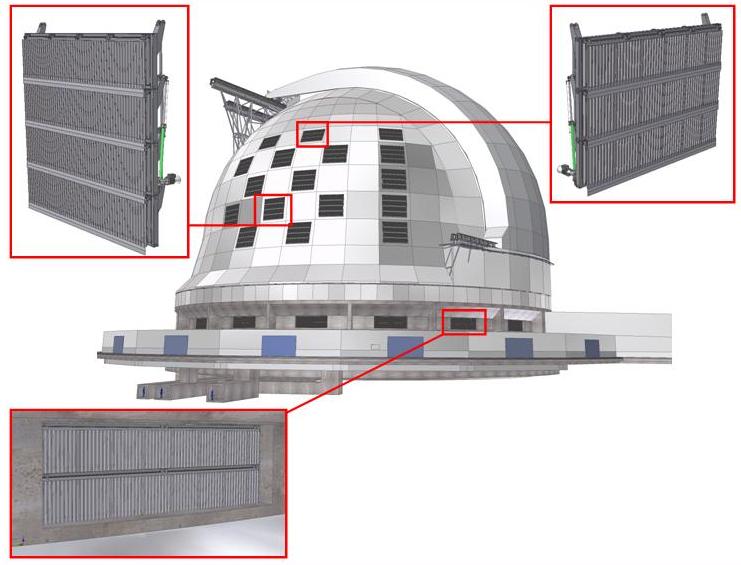

LOUVERS

89 louvers guarantee the correct ventilation inside the dome. Some of these are situated at the foundations, while others are placed on the rotating dome. One of the main features of this louvers system is the automatic closing process in case of sudden lack of electric power. It was designed in order to ensure the telescope the maximum protection. The louvers also provide the aeration inside the dome: the ones placed on the fixed part cover an area of roughly 230 squared meters, while the ones located on the rotating part correspond to an area of 1050 squared meters.

WINDSCREEN

The windscreen protects the telescope from the wind and it is installed in front of the opening of the Dome Slit Doors. It is a non-invasive solution, characterized by four aluminum forms powered by engines, which make them slide vertically.

ELECTRICAL PLANTS

All of the electrical plants of the dome have been designed to be found in the shortest way possible, to optimize safety and to standardize the equipment. For this reason, four transformation substations have been provided: two of them will be located along the circumference of the dome, while one will be placed on the chiller platform and the other on the telescope’s pillar.

DOME CONTROL SYSTEM

The Dome can be controlled through the dome local control system which interfaces with the telescope control system via a local area network, based on a fail-safe architecture. It is made of a series of controllers (CPUs) and a network consisting of control units, gateways, reducers, sensors, actuators, all of which are needed to control and supervise.

THERMAL CONTROL SYSTEM

The Thermal Control System consists of 6 Air Handling Units, placed in the auxiliary buildings’ area. Two air units (AHPUs) are made for cooling and pressurizing, while the other four (AHUs) perform the cooling alone. During the day, air is introduced in the telescope chamber through air ducts, which are isolated and positioned along the internal side of the dome’s pillar.

AUXILIARY BUILDINGS

All around the dome’s pillar, auxiliary buildings will be erected. These will be offices, meeting rooms, rooms designed for technical and support activities, which will all reach 20m of depth and 4.60m of height, made of steel. They will be placed below louvers opening and their structure is independent from the dome and its foundations.

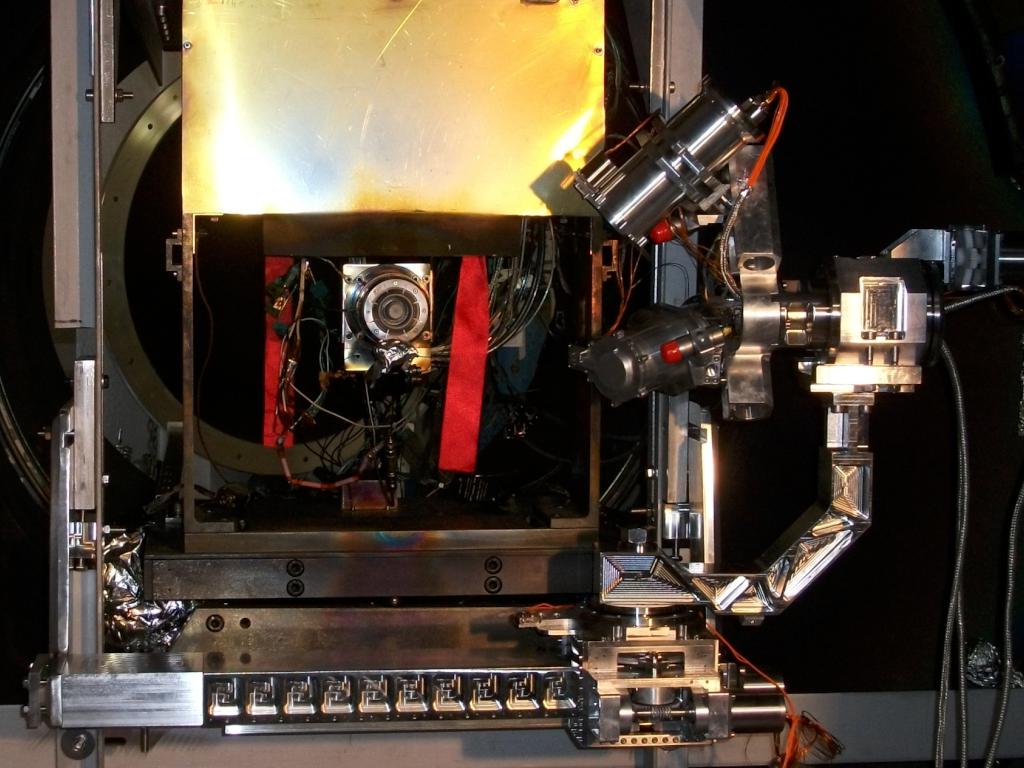

MOTION AND MAINTENANCE SYSTEMS

A primary motion system allows operational materials and equipment to move freely. A secondary motion system, connected to the primary one, performs the correct maintenance of the instrumentation inside the dome and telescope.

ACCESS EQUIPMENT SYSTEM

During the design of the dome access system, it was important to find a solution to provide access to people, materials and instrumentation inside the dome. Therefore, efforts were made to project different systems that would make it possible to access the dome from various levels such as stairs, elevators, platforms and walkways. In addition, a secondary access system will be provided in order to enter the dome for inspection and maintenance activities.

SEISMIC DAMPING DEVICES

ACe Consortium studied the possibility to avoid oscillation dampers on the main pillar to ensure the telescope the maximum stiffness possible.

For this reason, EIE GROUP implemented an innovative system of devices to damp earthquake oscillations: the Hydrostatic Bearing Pad System.

Science with EELT

Giant telescopes are considered one of the highest priorities of ground-based astronomy. E-ELT, with its 39m diameter “eye” will revolutionize our perception of the Universe, collecting 15 times more light than any of the most advanced optical instruments as of today.

The telescope will be provided with an innovative design that includes five mirrors with adaptive optics, which will be able to fix the deformations caused by the atmosphere ensuring high quality images.

The ELT will lead to many breakthroughs in Astronomy. It will make us understand the formation of the first objects, i.e. primordial stars, galaxies, black holes and the relationships existing between them. This extremely large telescope is designed to make detailed studies of the first galaxies and to follow their evolution through cosmic time. Thanks to this, we will able to observe the changing content of the various elements in the Universe with time.

One of the most exciting goals of the ELT is the possibility of making a direct measurement of the acceleration of the expansion of the universe. Such a measurement would have a major impact on our understanding of the cosmos.

Extrasolar planets will be investigated as well. ELT will provide us with measurements of the wobbling motion of stars perturbed by the planets that orbit them, but also with the direct imaging of larger planets and possibly even the characterization of their atmospheres.

Moreover, it will allow astronomers to detect water and organic molecules in protoplanetary discs around stars in the making, bringing humanity one step closer to understanding whether or not we are alone in te Universe.

Link to the webpage of EELT

ESO